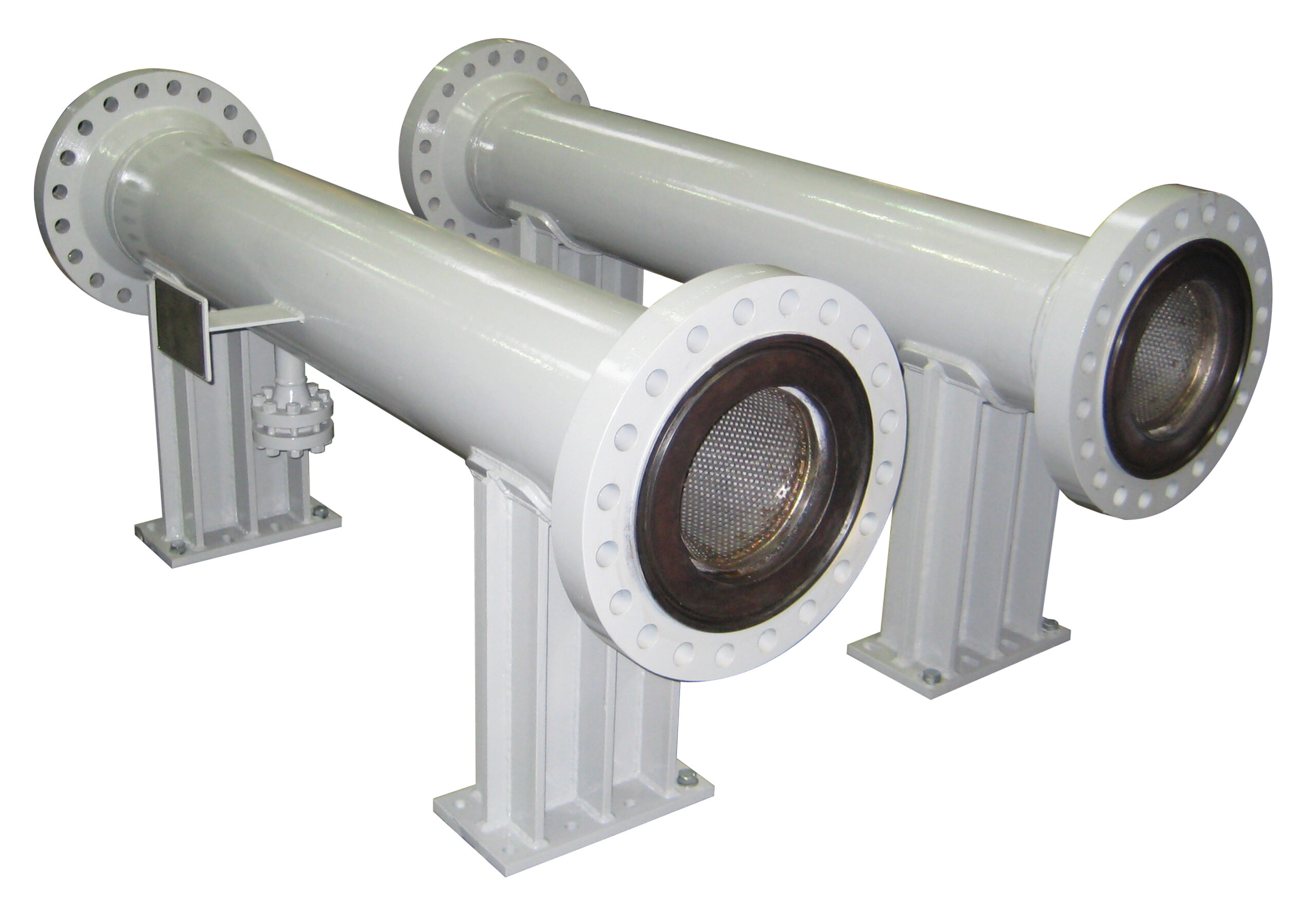

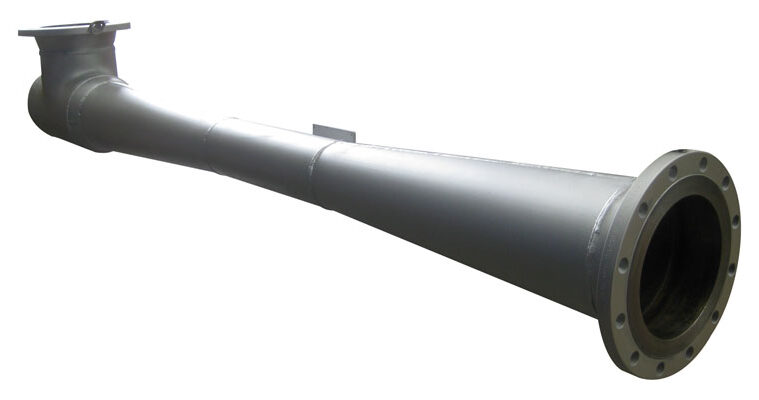

Transvac Start-Up Steam Ejectors; also known as Steam Jet Ejectors, Steam Eductors or simply Start-Up Ejectors, are often used on Sulphur Recovery Units for intermittently recirculating process gas from Hydrogenation Reactors to Desuperheater / Contact Condensers during start-up.

Stainless Steel and Carbon Steel are most commonly used for Start Up Steam Ejector applications. However, Transvac has extensive experience in providing Ejectors manufactured from exotic materials, should this be required.

Transvac will advise how much noise is generated by Start Up Steam Ejectors and if the noise level exceeds allowable site requirements.

If noise levels exceed allowable limits, typically 80 – 85 dB(A) @ 1m, Transvac can provide suitable equipment for noise mitigation. The most common approach is acoustic insulation of the Ejector and Inline Silencers.

Further information on noise and vibration mitigation can be found here.