Traditional Ejectors are fixed-design devices that are custom designed to perform at specific operating conditions. However, Transvac understands that processes are not always fixed and predictable and conditions can change over time. That’s why we invented our patented ‘Universal Design’ Ejector technology.

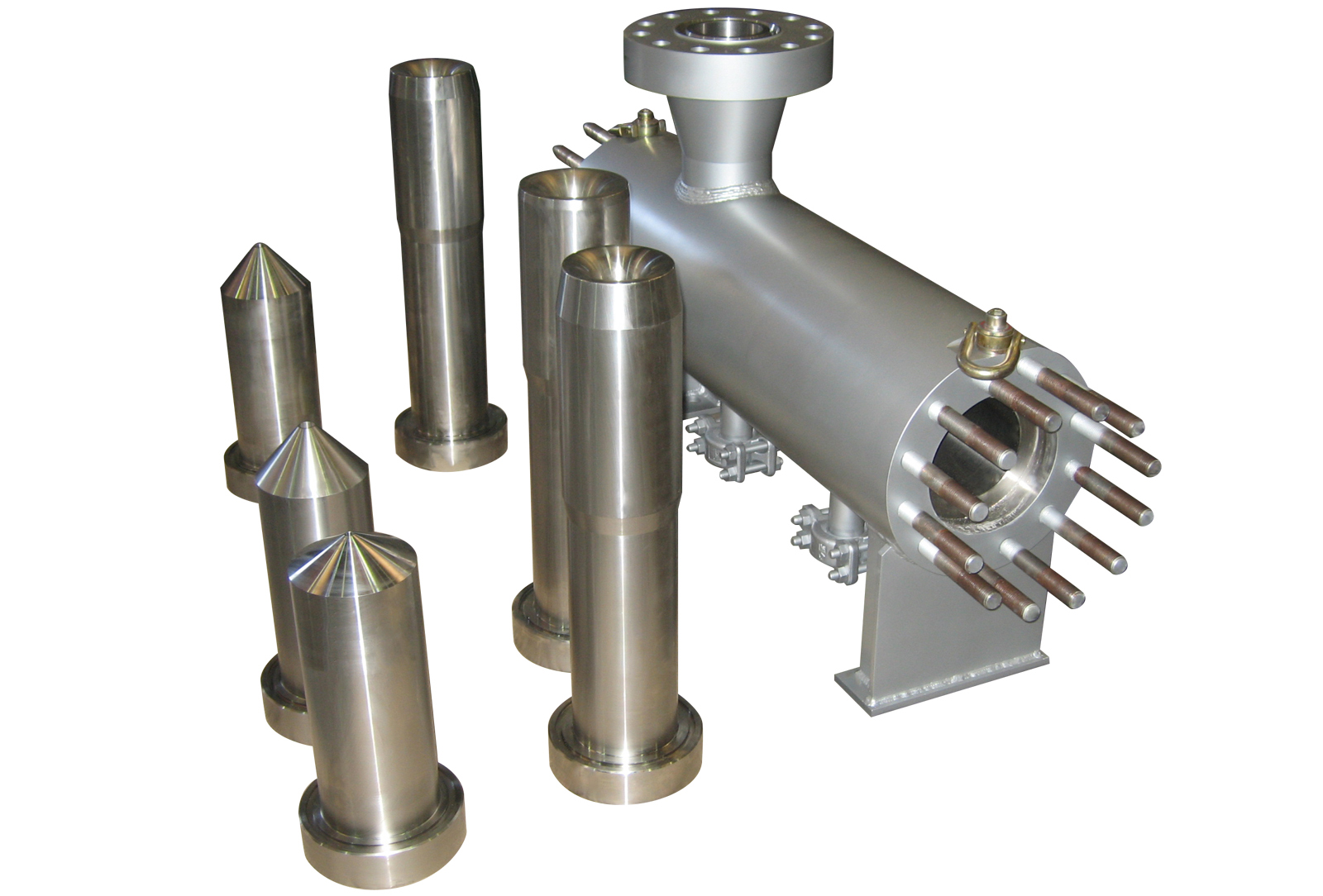

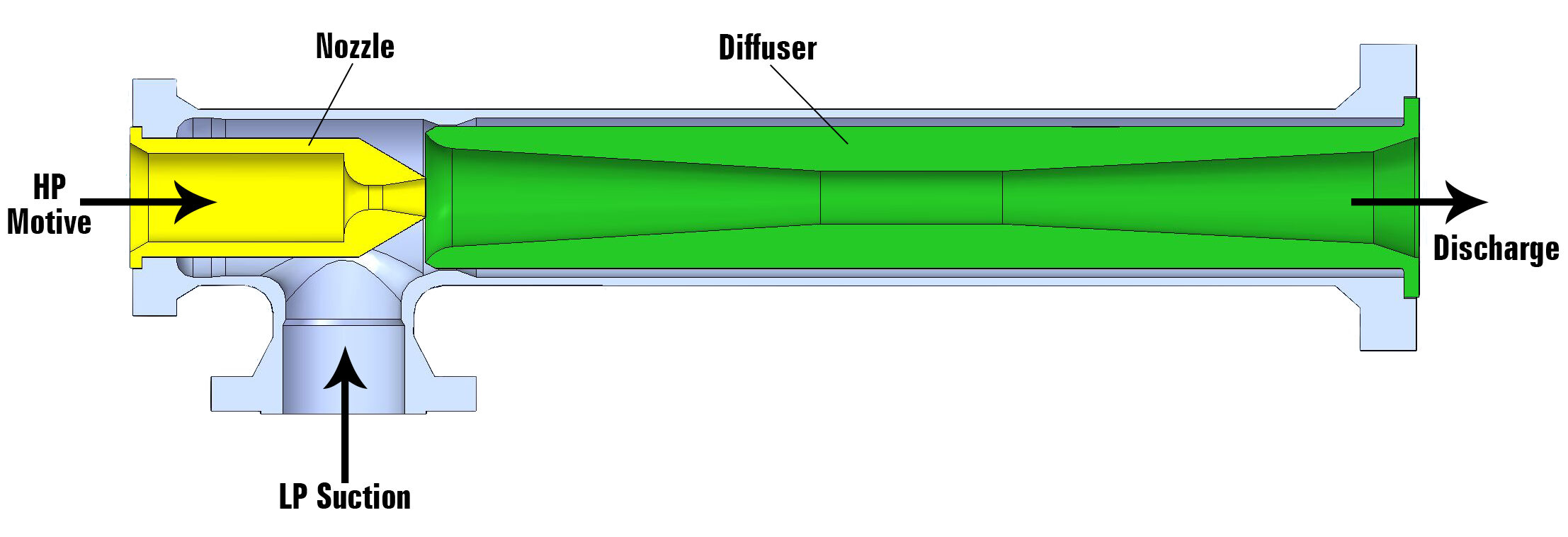

The patented Universal Design (UD) comprises an external pressure retaining shell (the Ejector body) into which two replaceable components are fitted, the Nozzle and Diffuser. The geometry of these two components give the Ejector it’s operating characteristics.

As process conditions change (such as declining Well pressures or a Flare Gas flow increase), the Universal Design Internals can be changed-out with new Internals which are optimised for the new conditions.

By changing-out the Ejector Internals at recommended intervals, high performance efficiency can be maintained, thereby maximising gas recovery from LP wells and from the field (or increasing gas recovery for Flare Gas Recovery applications). This is one of many factors contributing to the outstanding longevity and flexibility of Transvac Universal Design Ejectors.

A typical Universal Design Ejector. Both the Nozzle and Diffuser parts can be removed and replaced as required.

To maintain performance where operating conditions may change gradually over time. (e.g. declining Well conditions or Separator throughput)

The UD pressure retaining shell can be sized to suit future operating conditions to allow Internals change-outs with minimal disruption

UD Nozzle and Diffuser Internals can be simply changed-out to suit different operating conditions without affecting associated pipework

Manufacture of the UD Nozzle & Diffuser can be delayed until the last few weeks of a Contract, when operating conditions are finalised (e.g. when a new Well is completed), thereby reducing the programme and process design risks

Change-out of new UD Internals can be completed in one ‘shift’, using non-specialist personnel and standard lifting equipment

Less risk to a project if the predicted operating conditions are found to be wrong, because updated UD Internals can be supplied and installed quickly with no changes to associated pipework

UD design approach allows short-term Well boosting gains to be realised

Without Internals installed, the UD Ejector simply behaves as a section of pipework

UD Ejectors can be relocated to a new site with different operating conditions by installing new Internals

UD Ejectors are simple to install and are mechanically designed as pipework items in accordance with ASME B31.3