Powdered Activated Carbon (PAC) is small activated carbon particles, with a size that is predominantly less than 0.075mm, produced by milling or pulverising activated carbon. Thanks to its extremely porous nature and large surface area, it is effective at absorbing impurities, such as pesticides and organic material – often the cause of taste and odour issues in drinking water. This makes it ideally suited to tackle a range of water quality issues. However, the physical properties of PAC make it notoriously challenging to handle.

PAC Dosing is the process of adding or administering an amount of PAC into a specific volume of water. It is important to be able to accurately control the ‘dose rate’ for two reasons. Firstly, to ensure there is enough PAC to provide effective treatment. Secondly, to avoid unnecessary wastage of PAC through ineffective dosing practice or spillage. Our PAC Dosing solution, TransPAC has been developed to offer a flexible, practical solution to PAC Dosing. So Operators can enjoy the benefits of PAC without the headaches!

TransPAC is a cost effective and highly efficient PAC dosing solution. A portable system, without the need for building or groundworks, it provides a flexible, safe and secure home for your carbon dosing solution.

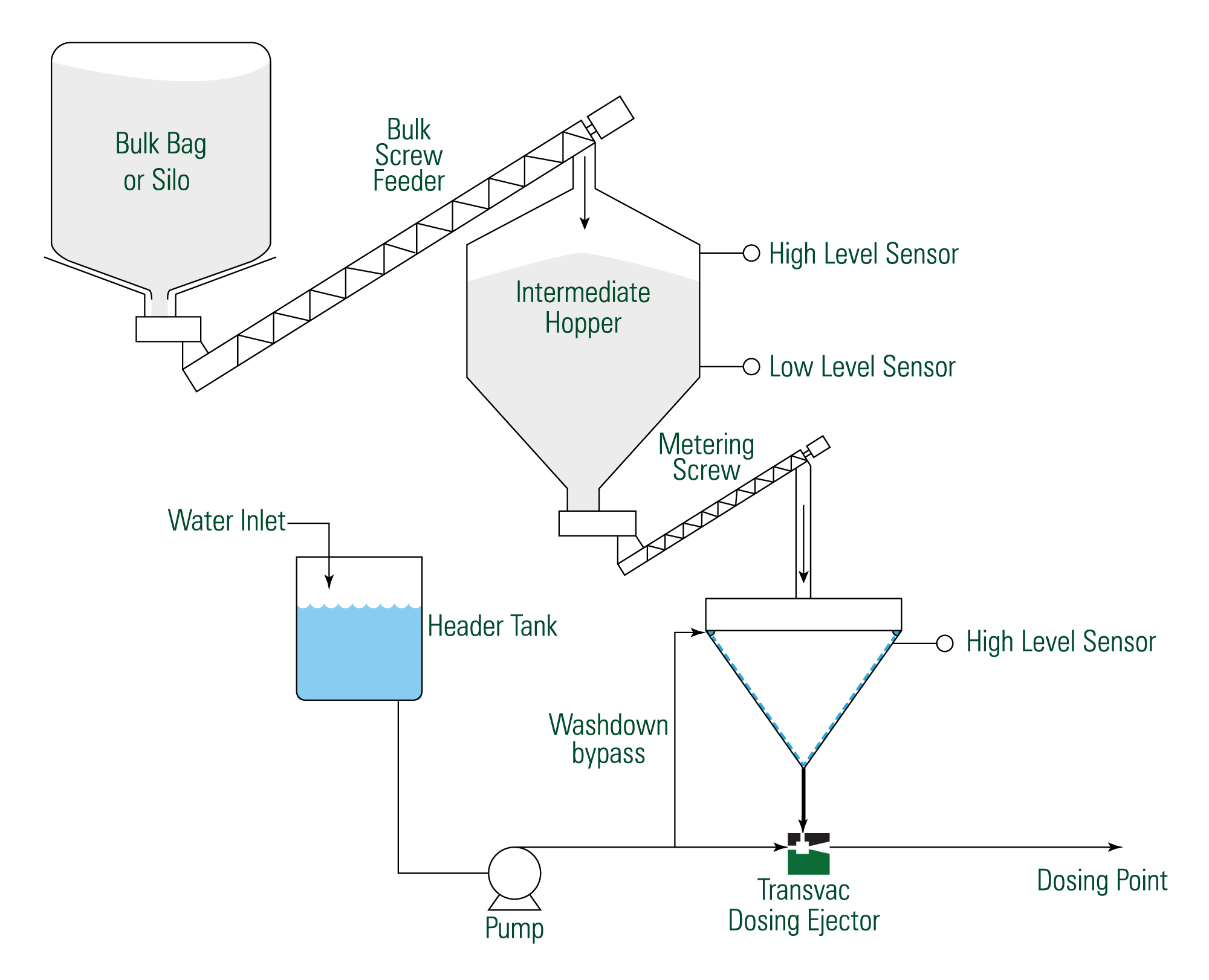

As standard, the system is equipped to dose carbon from either a silo feed or a bulk-bag mount. TransPAC provides once-through inline dosing, so there are no batch mixing tanks to contend with and the fully programmable control panel provides accurate and efficient dosing.

TransPAC has no ‘wet mixing’ moving parts, which provides unrivalled reliability. Its low maintenance control philosophy even flushes the lines clean on shut-down, so you can be confident of a hassle free start up, when you need it most.

It has been successfully implemented at many water and waste water treatment plants across the United Kingdom. Most importantly, it offers you a fast response option to resolve failing water standards, putting you back in control.

TransPAC shown with Bulk Bag Feed Option

TransPAC shown with Silo Feed Option

Activated carbon is widely used in the drinking water treatment process for the removal of organisms causing taste and odour complaints.

In some instances, Granular Activated Carbon (GAC) beds are used, however, these are huge CAPEX projects. Further to this, the OPEX remains very high, as the GAC requires regeneration at regular intervals.

Our range of dosing solutions offer a clean, efficient and flexible interface for handling PAC. Taste and odour problems are often seasonal, and sometime relatively short-lived. Our TransPAC solutions can easily be moved from site to site, giving you a fast and effective tool to deal with seasonal issues without the burden of large, slow and costly remedial projects.

Metaldehyde is a selective pesticide used by farmers and gardeners to control slugs and snails in a wide variety of crops. It is sold under a variety of brand names, generally as blue coloured pellets.

In certain locations, water companies have detected traces of Metaldehyde in the water they extract from rivers and reservoirs which, although at low levels, are above the European and UK standards set for drinking water. Unfortunately, some current treatment methods designed to remove a range of pesticides are not effective at reducing the levels of Metaldehyde in water.

Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) are commonly used in the water treatment process to remove pesticides. However, due to the characteristics of Metaldehyde, the life of Granular Activated Carbon (GAC) is significantly reduced, thus increasing the GAC regeneration frequency which, in turn, increases treatment costs and plant shut-downs. Powdered Activated Carbon does not have these operational problems and can be used to remove Metaldehyde. Find out more about how a TransPAC can tackle Metaldehyde.

Algal blooms occur when the nutrients getting into surface waters cause rapid growth in the algae present in the water.

It has caused sporadic problems in water treatment processes for decades. When water abstracted for drinking water treatment contains algal blooms, blockages can occur in filters and odours may develop in the treated water.

A simple solution to control algae bloom is adding required levels of powdered carbon (PAC) to the water. Transvac offers a range of dosing solutions, including the containerised TransPAC system.

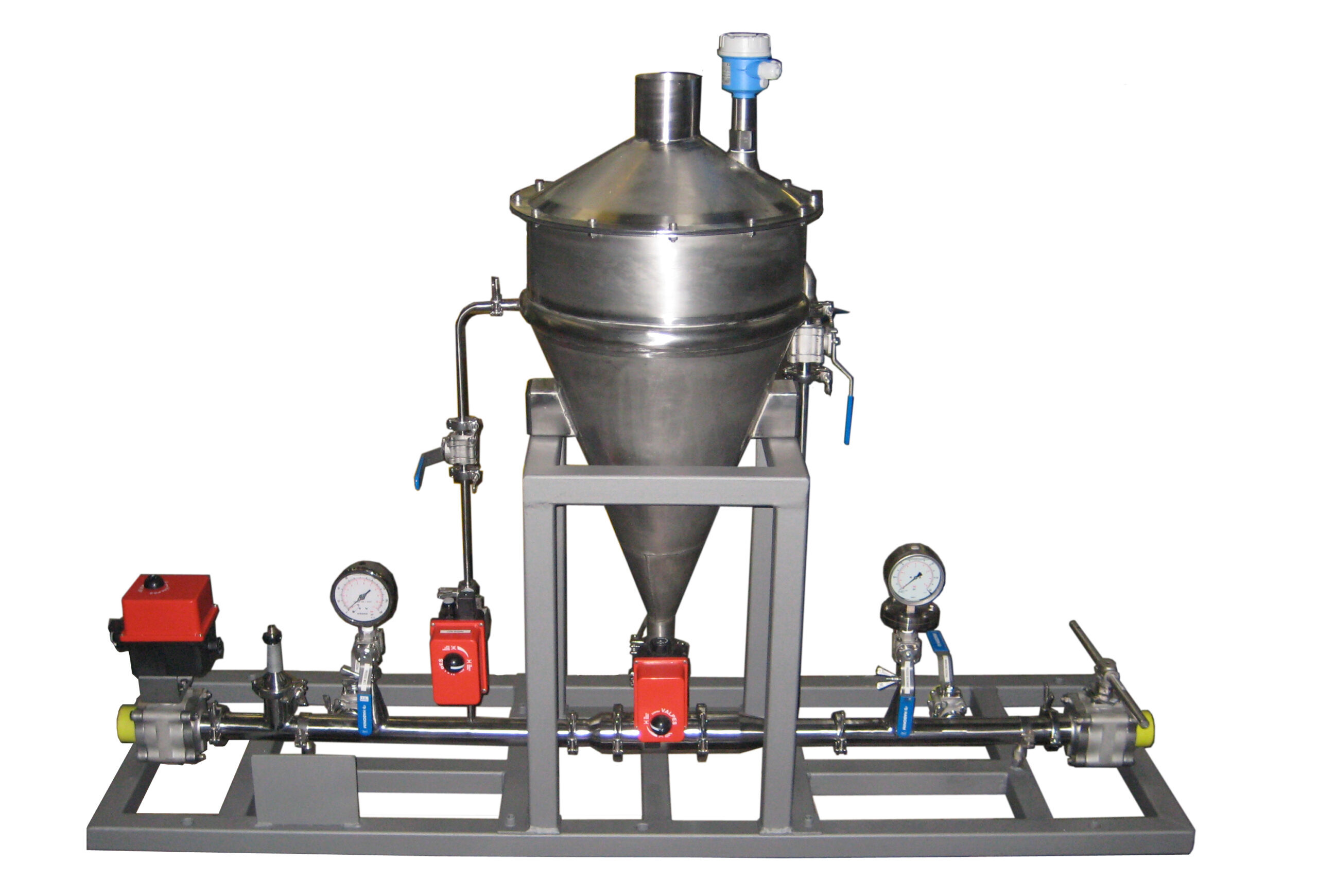

If you have a requirement for a PAC Dosing system within an existing building, that’s no problem! Transvac can supply custom built, stand-alone skid packages without the container. Each unit is tailor made to match the dosing needs of your facility and can be equipped with booster pumps and controls, as required.

Similar to a containerised TransPAC, our skid dosing packages can be fed via bulk-bag or silo systems. Automatic and manual dosng control is available, as well as optional WRAS approved header tanks. To enable integration around existing infrastructure, the layout is flexible. Hygienic options are available as well as duty-standby systems.

Transvac Size 2” Skid Mounted Liquid Jet Solids Pump System – for Welsh Water

Transvac Duty / Standby PAC Dosing System and Pump Skid – for Yorkshire Water

Transvac Size 2” fixed design PAC dosing system with winch – for United Utilities

Transvac Fixed PAC Dosing System with screw feed – for Southern Water