Ejectors are an effective tool to increase production, enhance recovery and extend the the life of mature fields. This is achieved by lowering the back-pressure on a well (or a number of wells) imposed by the downstream pipeline and process equipment.

The reduction in the flowing wellhead pressure (FWHP) will result in an increase in production. In many cases, it is also expected that the reduction in the FWHP will help to stabilise production and improve the flow regime of fluids passing through the well bore.

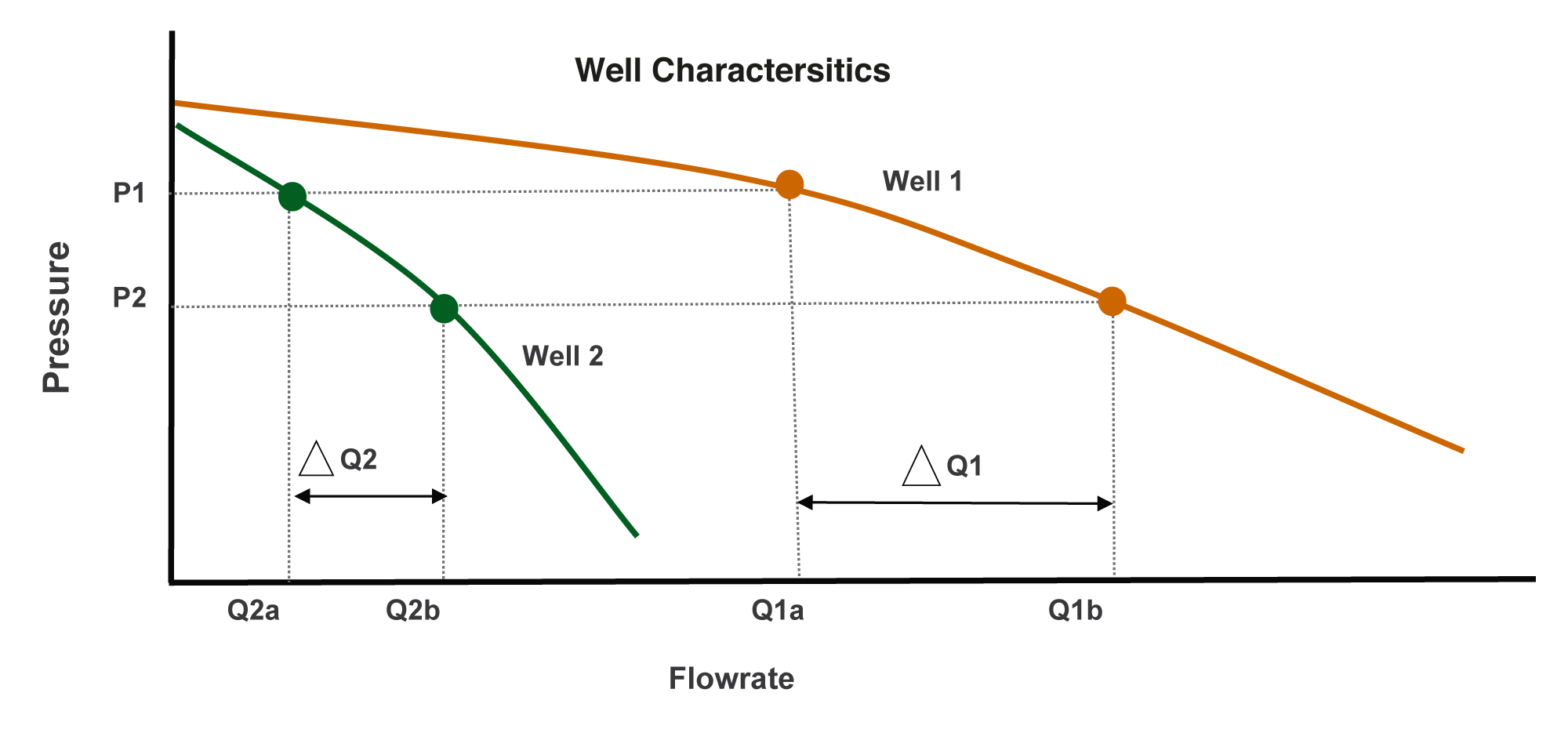

Each well will have its own characteristics. Some high pressure wells decline very fast, some very much slower. The good news is that even with a fast-declining high pressure well, the economics of an Ejector project are compelling. The energy can be used efficiently and effectively to boost production from a low pressure, well, providing a significant payback of extra production.

The increase in production depends on two main factors;

The PI value is provided by the Operator, but in many cases an accurate value for the PI at the reduced FWHP is not available. The only way to establish the PI of the well at the reduced FWHP is to test the well at the reduced FWHP, using a Test Separator, for example. Alternatively, Operators can provide best-estimates, based upon their experience and understanding of their field.

The achievable drop in FWHP is dependent on factors such as the HP / LP pressure ratio and flow ratio (across the Ejector) and other factors such as the type of motive flow (gas or liquid) and the amount of liquids in LP gas (in gas production applications) and, in the case of the oil production, the combined flow rate of LP gas and liquids.

In this example, the production boost from Well 1 is greater than that from Well 2

for the same amount of back-pressure reduction.

The diagram below shows typical Ejector installation locations within an upstream process path. Please note; it is possible to implement more than one Ejector opportunity at a time. Also, Ejectors can be used in addition to other existing EOR / production optimisation techniques, such as Gas Lift or ESP’s.

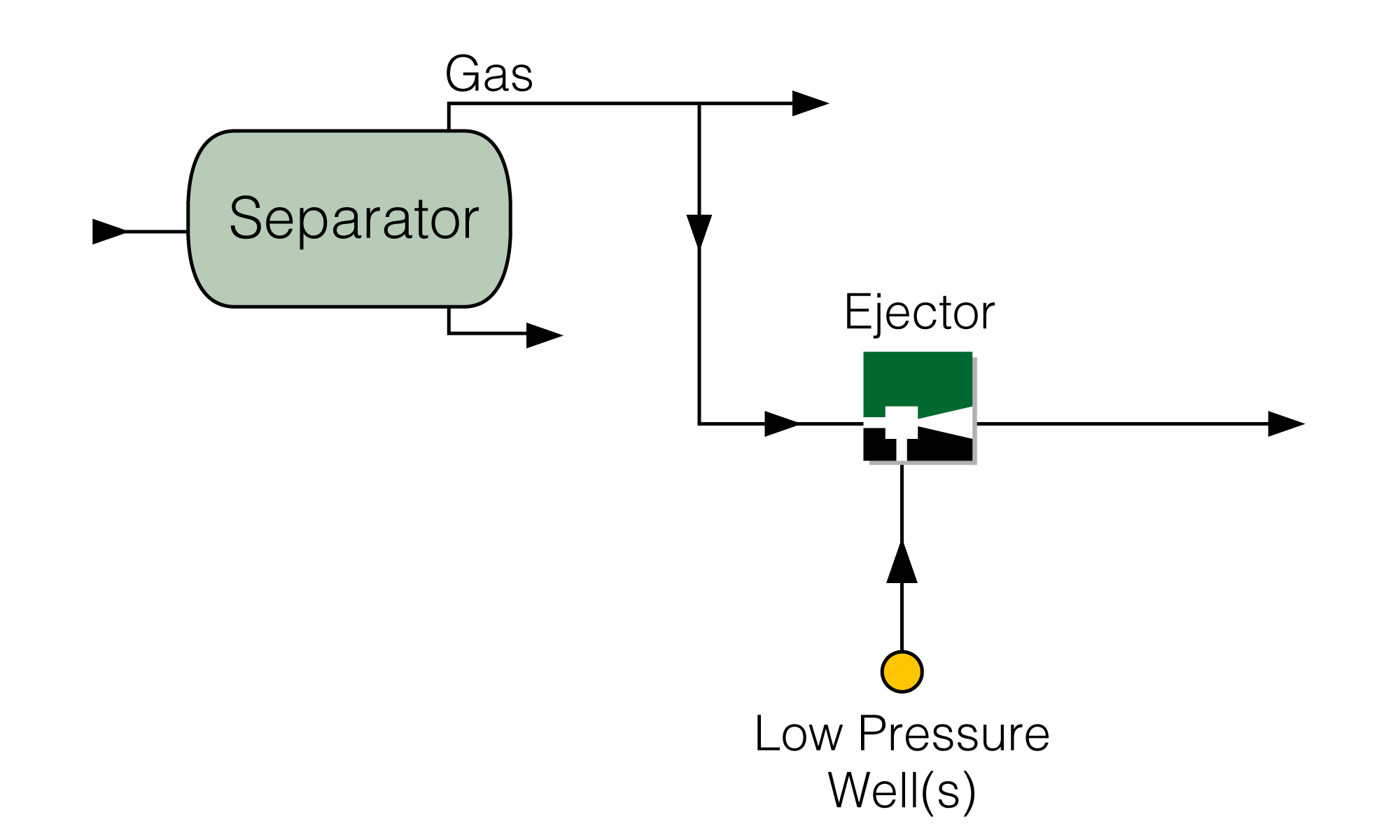

An Ejector is used to reduce the separator operating pressure by entraining the gas outlet stream. As a result, back-pressure applied to any upstream wells is also reduced, thereby stimulating both Oil and Gas production. For gas fields, the reduced pressure also increases pipeline velocity, which can be beneficial to clear liquid slugs, condensate etc to stabilise production.

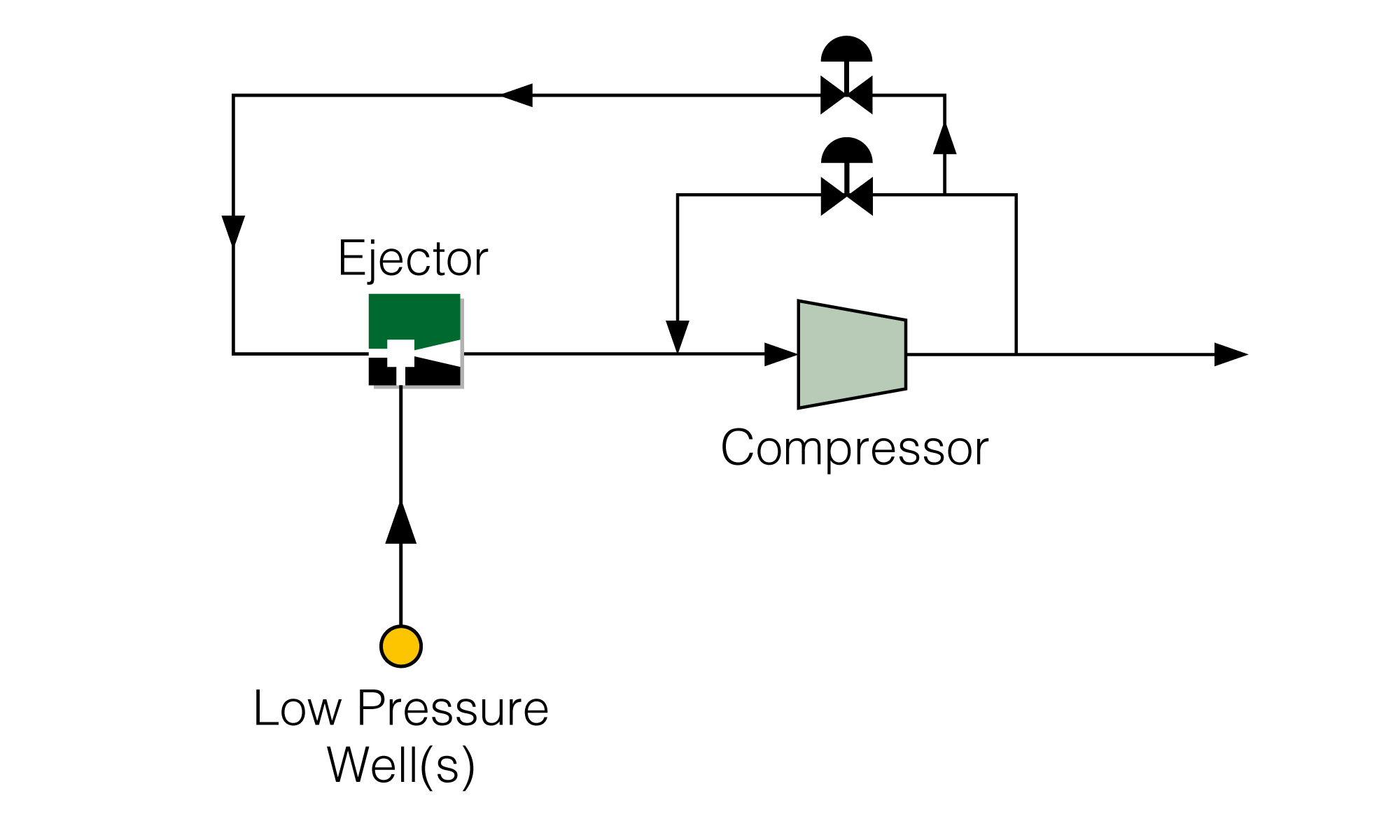

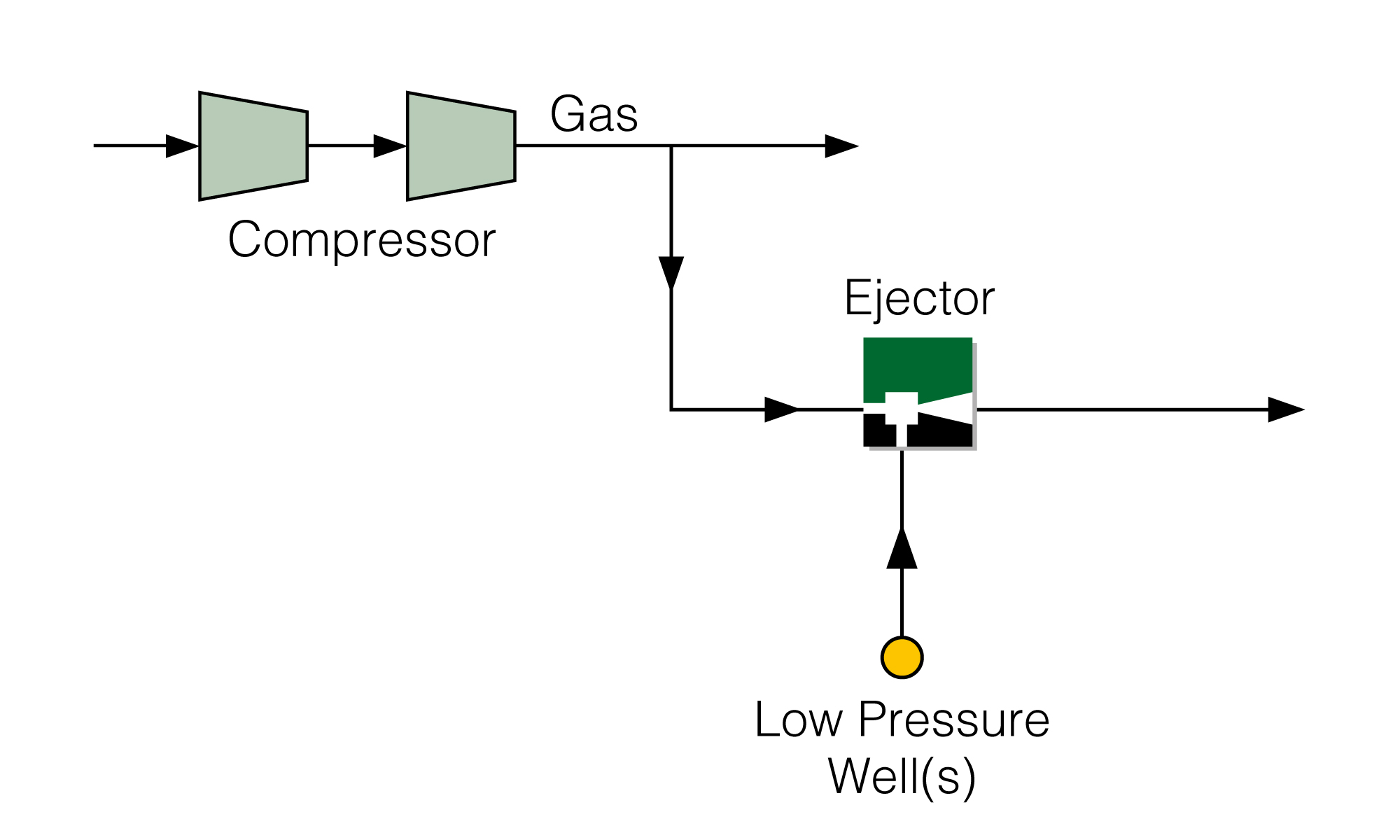

An Ejector is used to act as a new 1st-stage compressor, offering a lower inlet pressure than the original compression system. This technique reduces the back-pressure on upstream wells or production equipment, thereby stimulating extra production. The Ejector then compresses the stream and discharges it at the required (or improved) compressor inlet pressure.

LP Compressors can often become a bottleneck for production. In this option, an Ejector is employed to offer additional compression capacity. Gas is discharged from the Ejector to meet either an inter-stage pressure or compressor outlet pressure. In some cases, the Ejector can entirely replace an LP compressor, eliminating maintenance / OPEX.

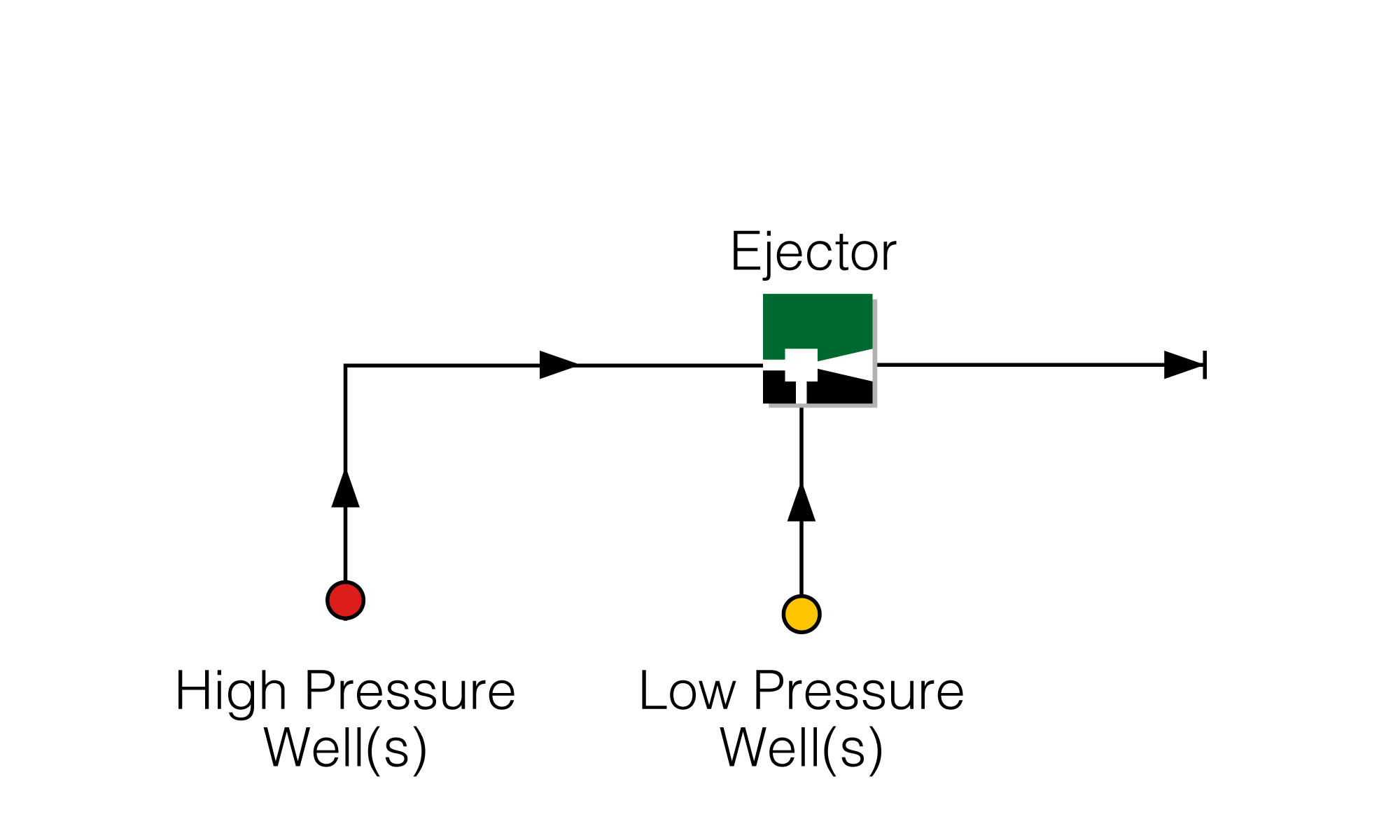

An ideal Ejector motive stream can often be provided by high-pressure wells. (The ‘high pressure’ does not have a specific value, rather it is high pressure relative to the low pressure wells and the required Ejector discharge pressure.)

For example, very often, newly-drilled wells operate at an elevated pressure. Early in the life of the well, this energy can be captured and used by an Ejector, rather than wasting or throttling it back.

Some fields / production facilities also operate with a high pressure and a low pressure line / tie-back. An Ejector can boost low pressure wells up and into the low pressure line, by using some flow from the high pressure line as its motive.

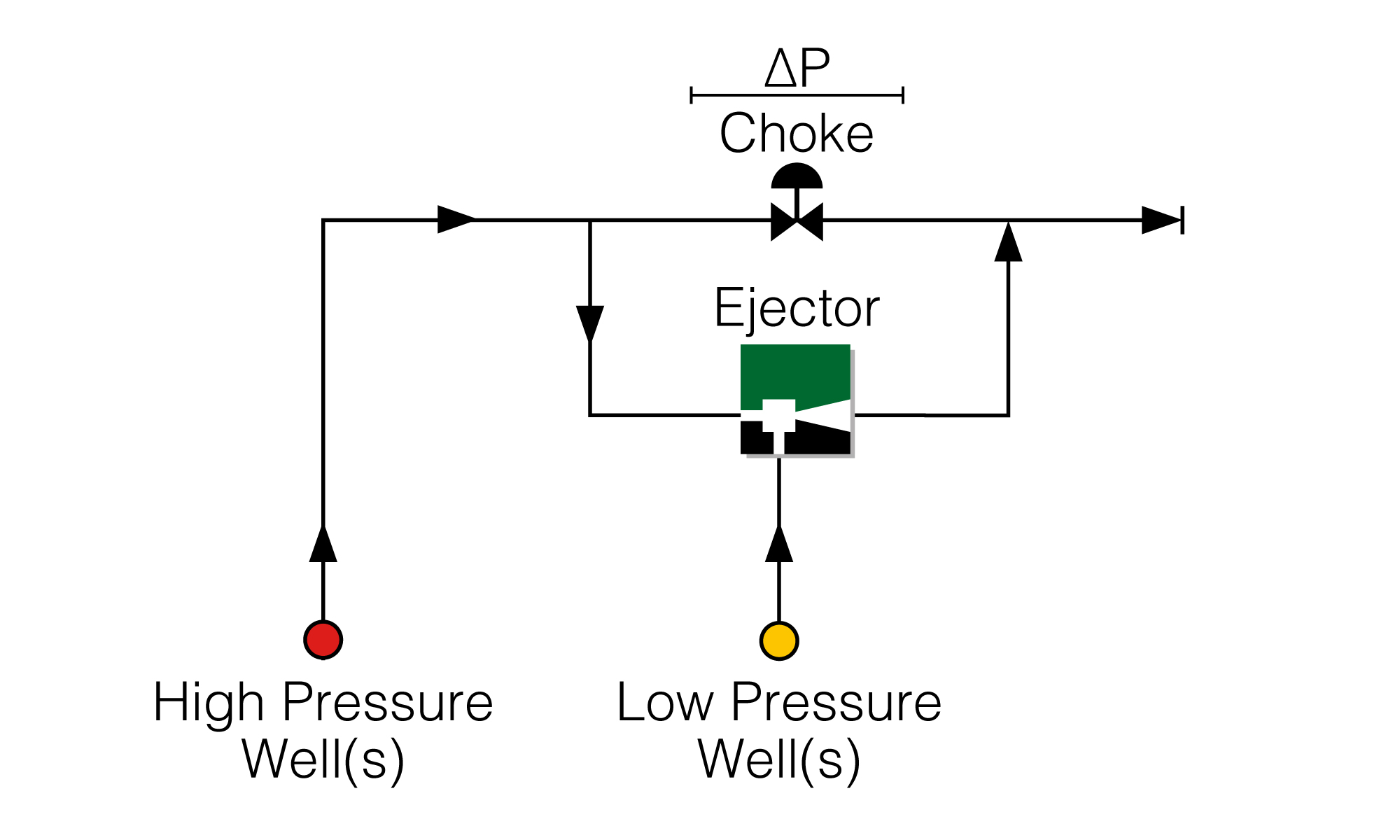

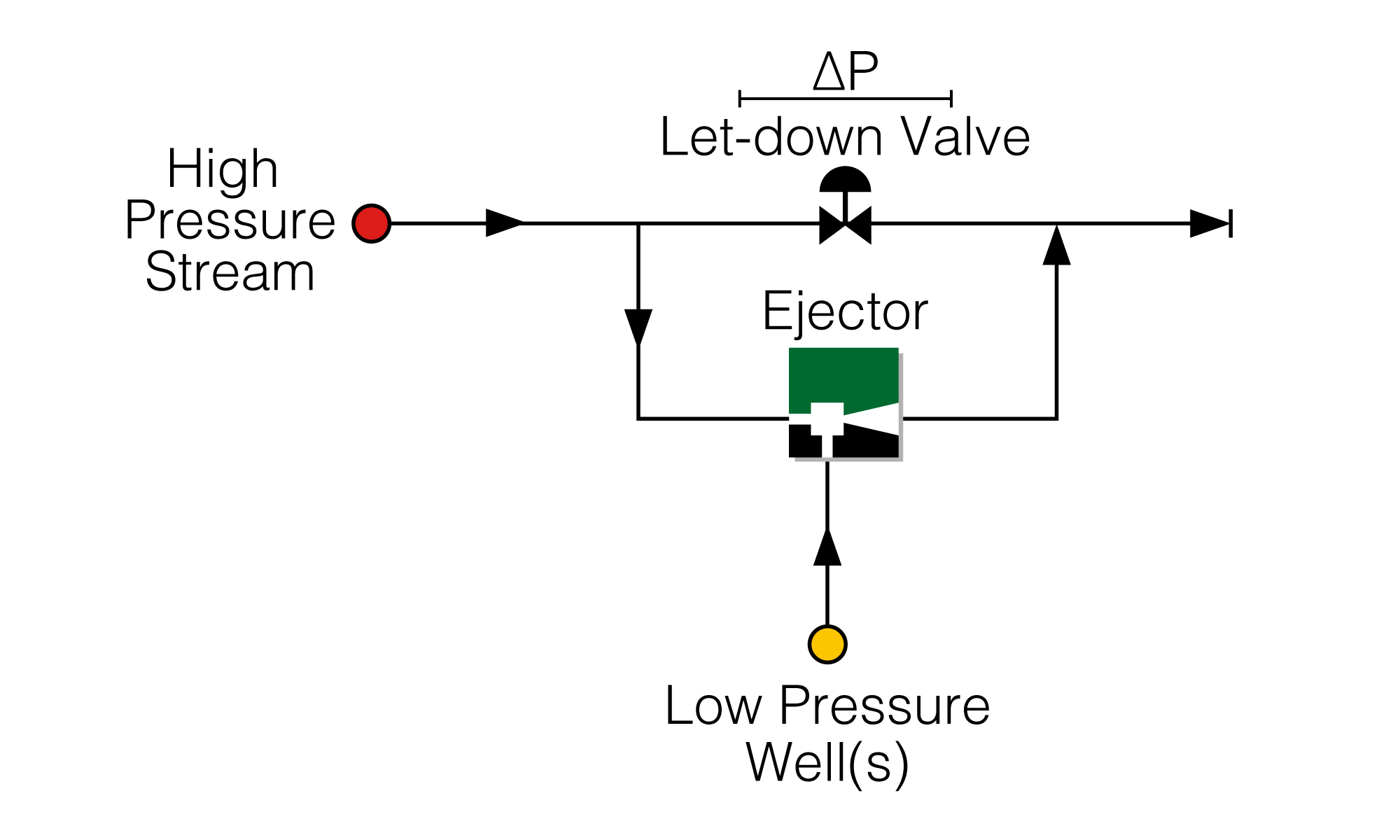

Transvac has used this technique effectively in upstream oil & gas, where high pressure Wells are being choked. Rather than wasting the pressure energy across the choke valve, the Ejector nozzle becomes, in effect, a choke and uses the energy usefully. The available high-pressure energy is used to drive an Ejector to assist weak, low pressure wells – or even revive dead / shut-in wells!

In some cases it may be beneficial to combine multiple high-pressure wells to provide the Ejector motive stream. Likewise, it may also be possible to assist multiple low-pressure / mature wells with one Ejector. Our team at Transvac can advise on this, based upon your specific well conditions.

Pressure let-down is available where high pressure streams are being fed into low(er) pressure systems. Rather than simply losing pressure energy across a valve or similar pressure let-down device, an Ejector can be driven.

The Ejector performs the same required pressure let-down on the motive stream. This is achieved across the Ejector nozzle. In doing so, the Ejector is activated and can also perform a useful compression duty, such as boosting well production, or lowering back-pressure on a separator.

This technique utilises otherwise-wasted energy, and therefore operates for free!

As production rates decline over time, there are many existing gas compressors operating inefficiently in constant recycle conditions to maintain performance. When in recycle mode some high-pressure compressor discharge gas flow is diverted and lowered in pressure to the compressor inlet.

The energy wasted across the recycle (anti-surge) valve can be used to ‘drive’ an Ejector to lower the pressure on LP (often marginal) wells thereby boosting production and sometimes bringing ‘dead’ wells back to life.

This method of boosting LP well production is achieved ‘for free’ by making use of waste energy. In many instances where existing compressors cannot meet the required pressures of LP wells it a cost-effective way of maintaining and boosting gas production without the need to re-wheel or replace compressors.

Also, the performance of a compressor often benefits from the addition of extra gas flow.

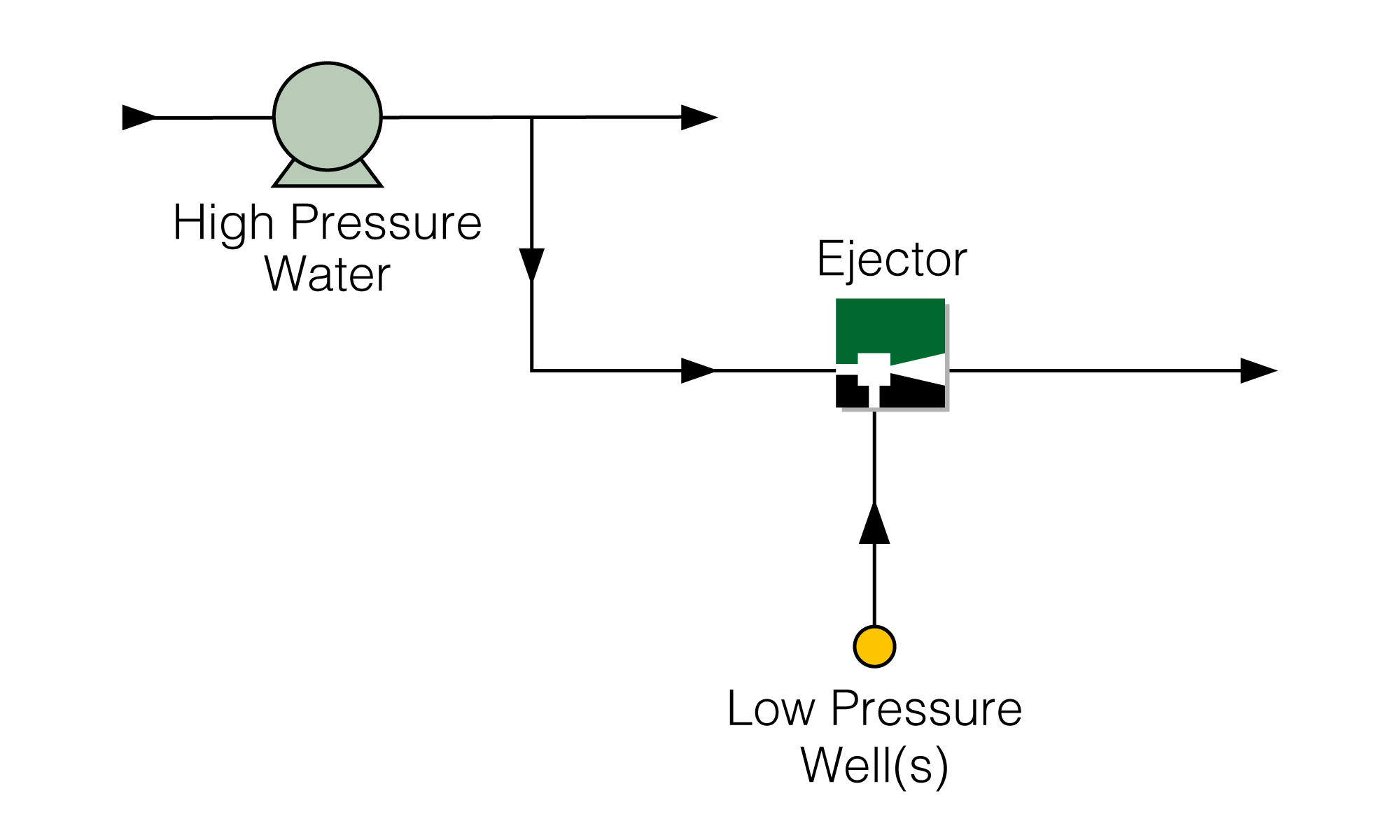

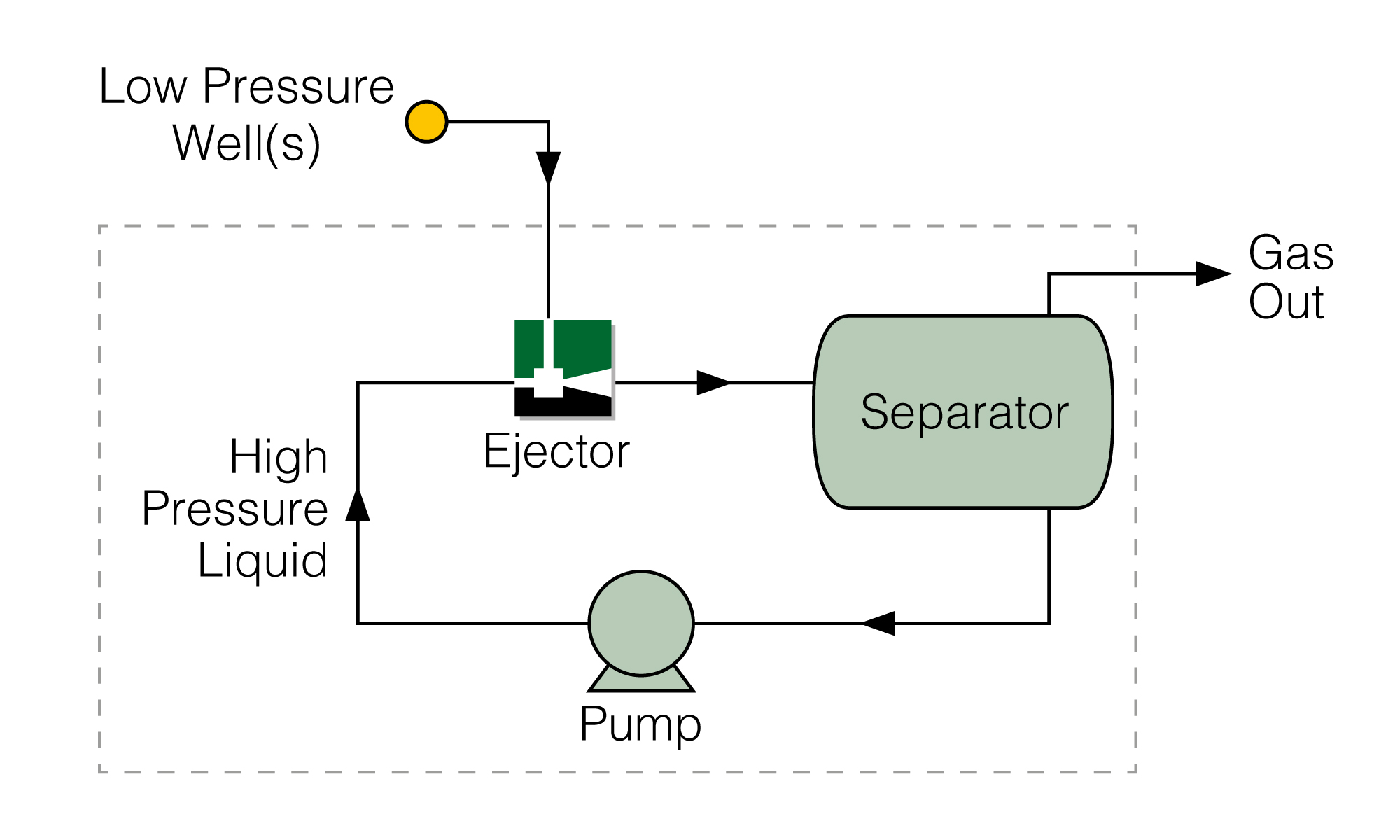

Transvac’s has made huge advances in the efficiency and capability of liquid motivated Ejectors. Offering very high compression ratios, these optimised Ejector designs open the door to a wealth of new applications throughout the Upstream and Downstream Oil & Gas Industry. The diagram shows just one simple but highly effective way in which operators can make use of this technology for enhanced recovery.

Typically, injection water or produced water is employed to motivate the Ejector, thus making use of existing facilities – perfect for brownfield developments. The Ejector can entrain and compress gas from a number of sources including a separator, manifold or individual well. The resultant reduction of backpressure on the upstream process delivers a boost to production and promotes steady flow where liquid loading is an issue, particularly in long tiebacks.

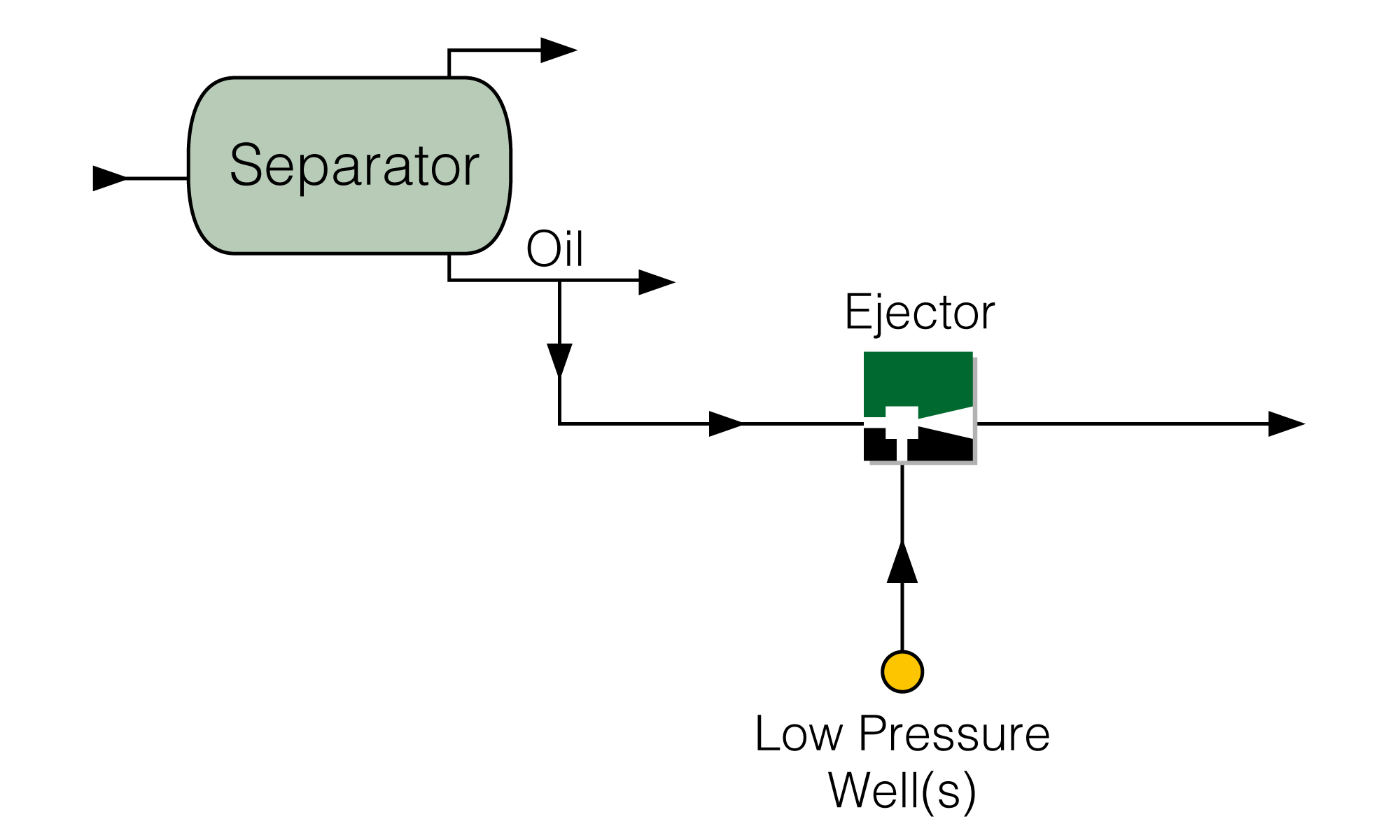

Similar to using high pressure water, oil can be used effectively to drive an Ejector. Transvac’s advances in the efficiency and capability of liquid motivated Ejectors includes the use of oil as a motive stream. The diagram shows the example of taking high pressure oil from the outlet of a high pressure separator. (In practice, this may also contain some water.) There is an abundance of facilities with two, three or more separation stages, which could offer excellent opportunities to drive an Ejector. Aside from ‘production boosting’ opportunities, this technique can also be used for Flare Gas Recovery.

High pressure oil can also be taken from oil export lines or after oil (or oily water) pumps where pressure has been boosted. Typically only a small side stream of flow is required to motivate the Ejector.

With this opportunity, a Gas Ejector can be motivated with high pressure gas. The gas can be taken from a suitable point at the outlet of a high pressure separator.

The high pressure gas is simply ‘borrowed’ to motivate the Gas Ejector after which, it is returned into the production process. Of course, the pay-off is achieved through activation of the Ejector which boosts production from upstream process / wells.

High pressure gas can often be found further downstream in the production process. This includes after a high pressure compression train or after sales gas / export gas compressor.

Where Gas Lift is being used as part of an EOR strategy, an Ejector can use some of the high pressure lift gas as a motive stream.

The high pressure gas is simply ‘borrowed’ to motivate the Gas Ejector after which, it is returned into the production process. Of course, the pay-off is achieved through activation of the Ejector which boosts production from upstream process / wells.

Where an existing motive stream is not available, Transvac can provide one!

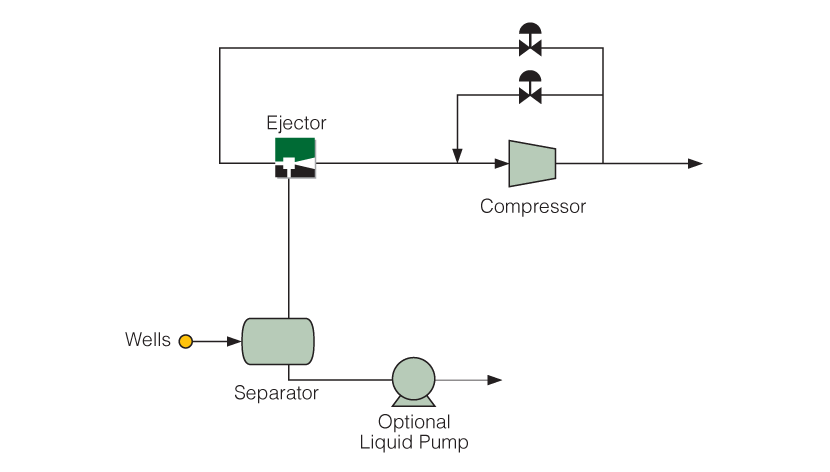

A ‘Liquid Jet Compressor’ (LJC) Recirculation Package utilises a high pressure pump, to provide a suitable motive to a LJC Ejector which entrains and compresses gas. The discharge of the LJC is multi-phase, with both gas and liquid. Therefore, the package includes a separator to allow the process gas stream to be discharged to downstream processing. The water / liquid outlet is recirculated back to the pump suction. This means that the solution does not require constant fluid feed, as it is recycled.

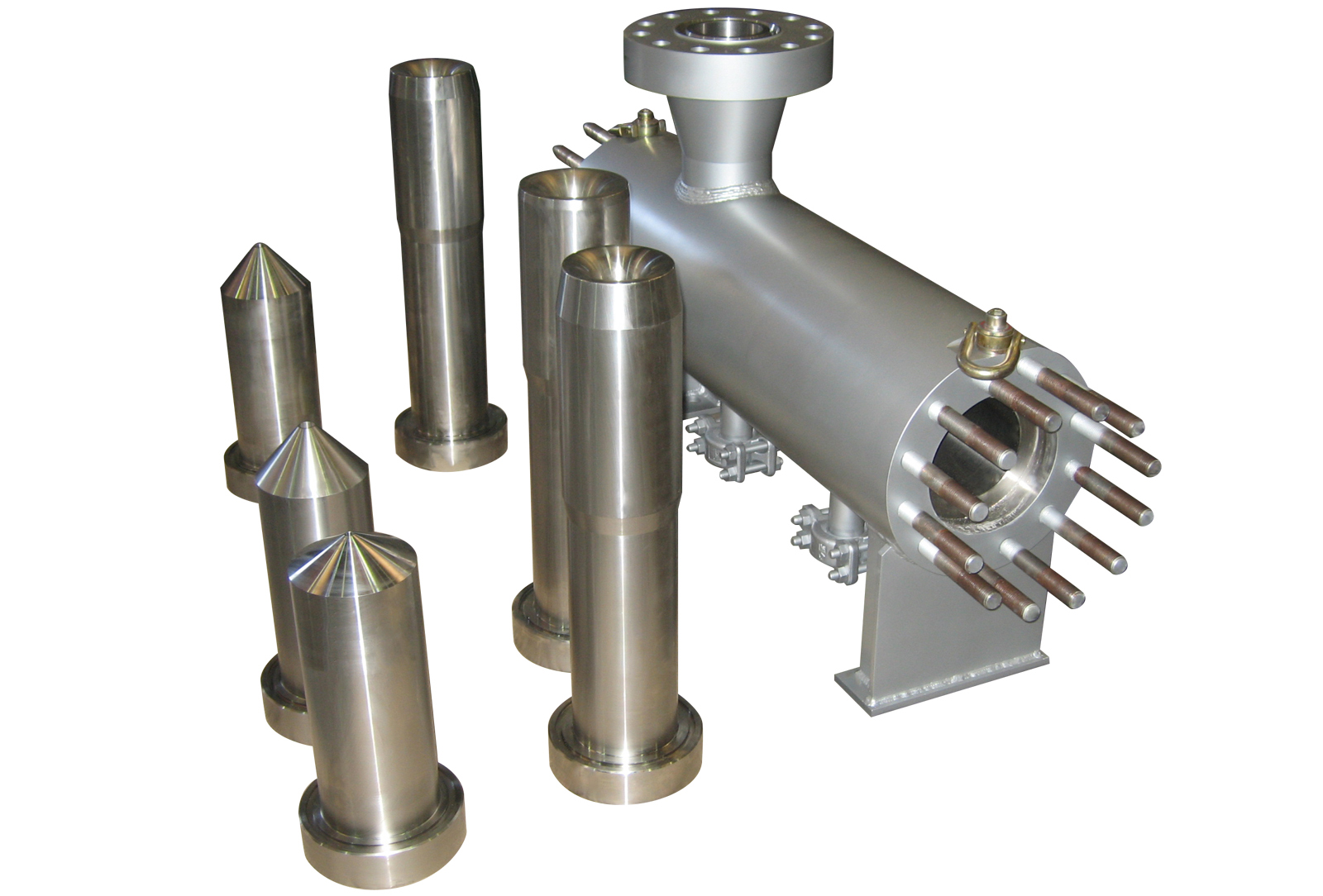

Transvac is well-equipped to carry out fast-track projects, in as little as 8 weeks. This means short-term opportunities can be realised quickly.

At site, an installation of this kind typically requires only a simple pipework tie-in and can be carried out quickly and easily. Relative to traditional compression equipment, the compact size of Ejectors is ideal for retrofit into existing facilities, such as offshore platforms, where space and weight restrictions apply.

Transvac’s ‘Fast-Track’ service has proven highly valuable on multiple projects, where existing mechanical compressors have failed or are not yet in service. Our fast response solution kept production flowing – with great economic benefits.

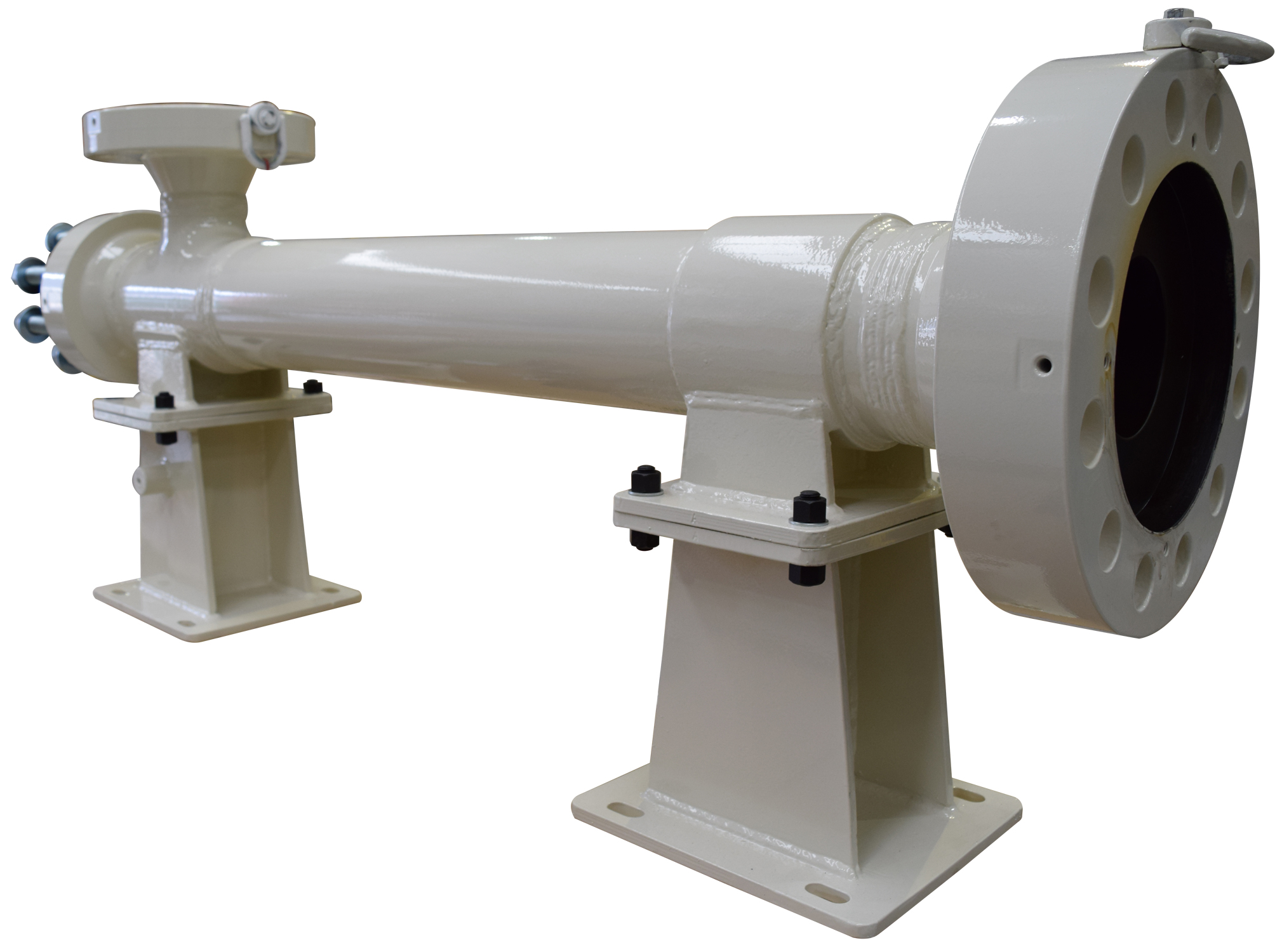

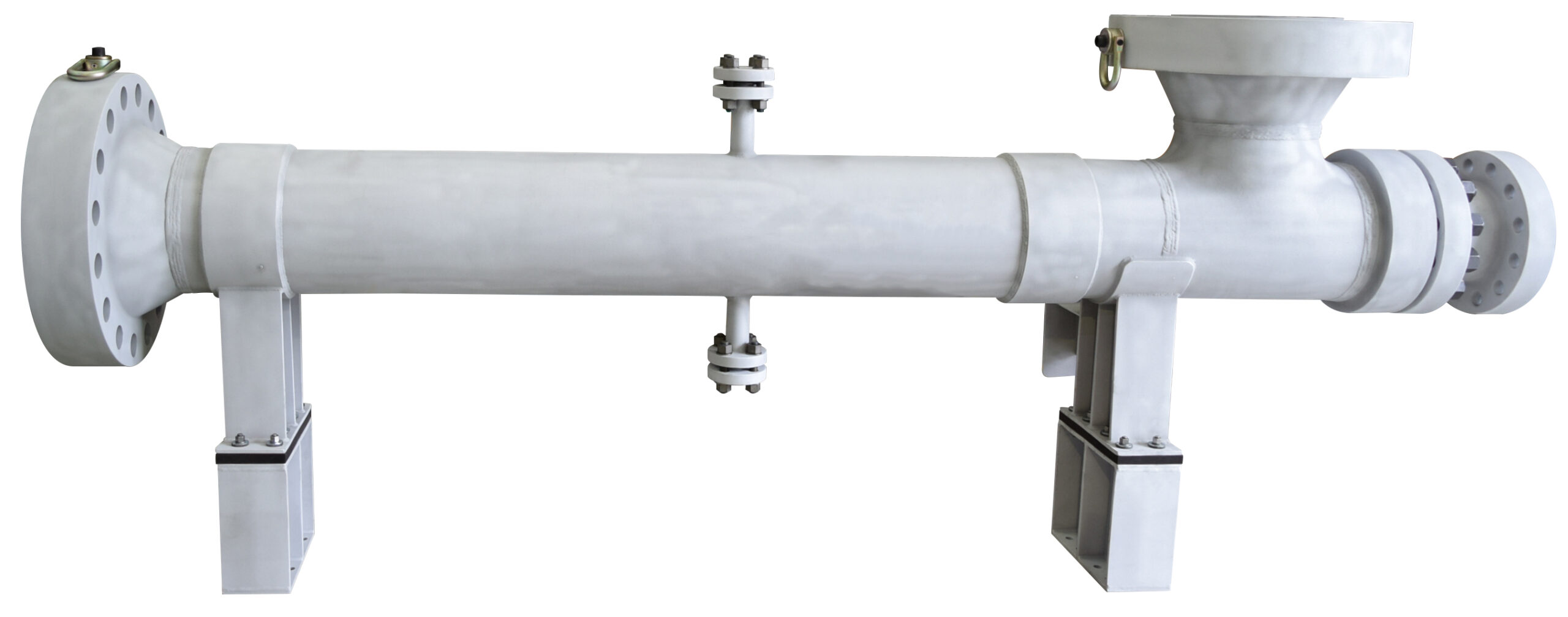

This Gas Ejector for Shell, UK North Sea,

was designed, manufactured and installed within 12 weeks.

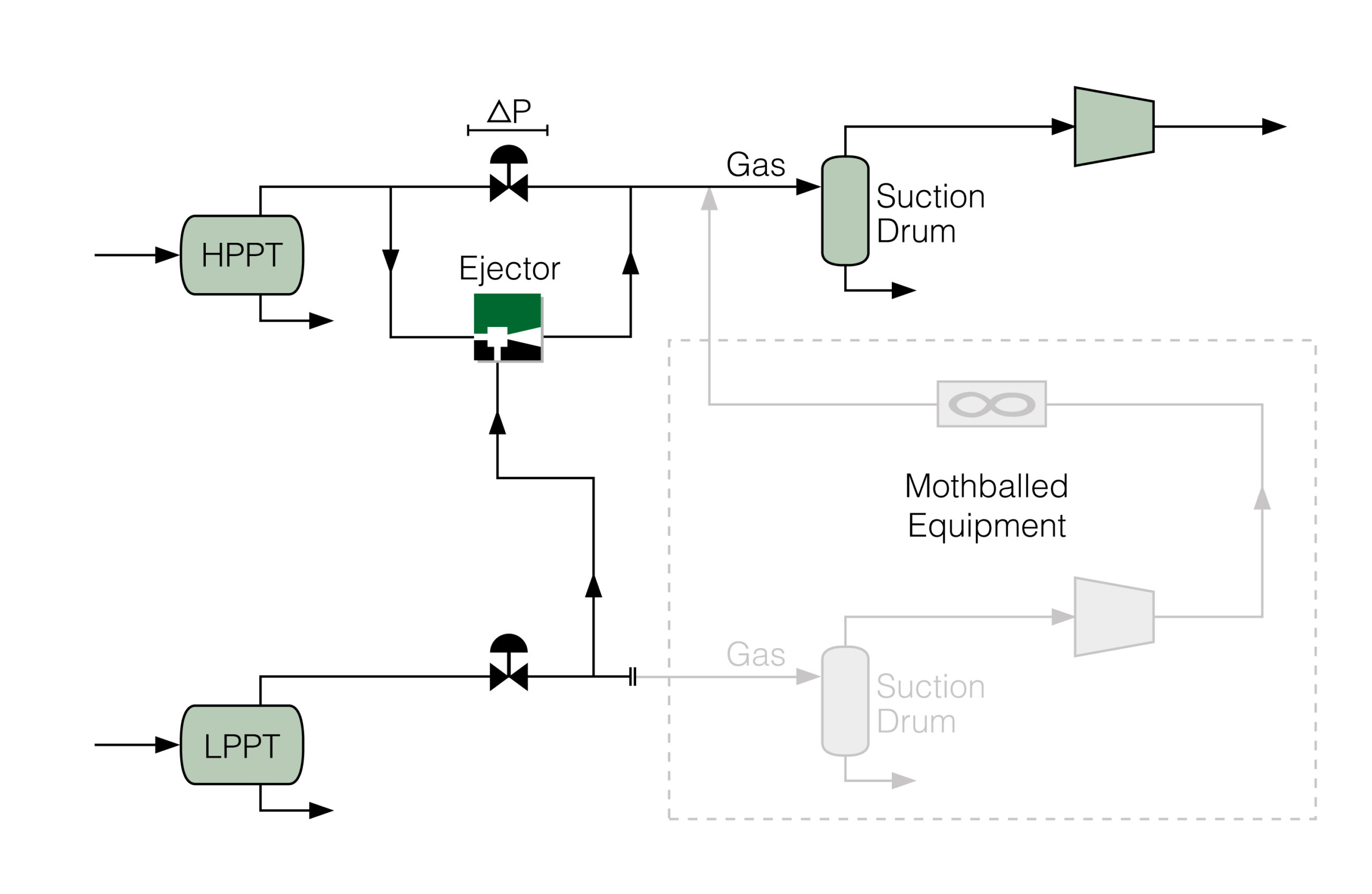

In a recent project in Saudi Arabia, a pressure let-down opportunity was identified at a gas and oil separation plant (GOSP), which operated with high and low-pressure gas compression trains.

Transvac was able to install an Ejector package which utilised the otherwise-wasted pressure energy, lost across a valve in the high-pressure (HPPT) stream, to entirely eliminate the low-pressure (LPPT) mechanical compressor.

Not only does this Ejector package operate using existing waste energy, it eliminated the running costs and significant maintenance of the low-pressure compressor.

This technique clearly demonstrates the opportunity to use Ejectors as an alternative to ‘traditional’ gas compressors.

Please also visit our Gas Compression page for further Compressor replacement / Compressor alternative opportunities.

Multi-phase production can be enhanced using this simple technique to reduce separator pressure. The Ejector can be ‘driven’ using energy from compressor recycle gas, HP well gas, or even HP water (such as injection water, although introducing a liquid would require downstream separation). By lowering separator pressure, it is simply reducing the backpressure (resistance) on upstream production process, which increases production.

Utilising waste energy from a compressor recycle has been successfully used to offer flow assurance in a 50km subsea tieback, which had been suffering from intermittent production due to liquid/condensate build-up in the pipeline. Using an Ejector to lower the existing separator pressure on the platform increased the specific volume and velocity of the suction gas in the long tieback, resulting in a steady enhanced recovery over a number of years. As compressor recycle gas was used to drive the Ejector, no ‘new’ energy was required, making the project a win-win on many levels.

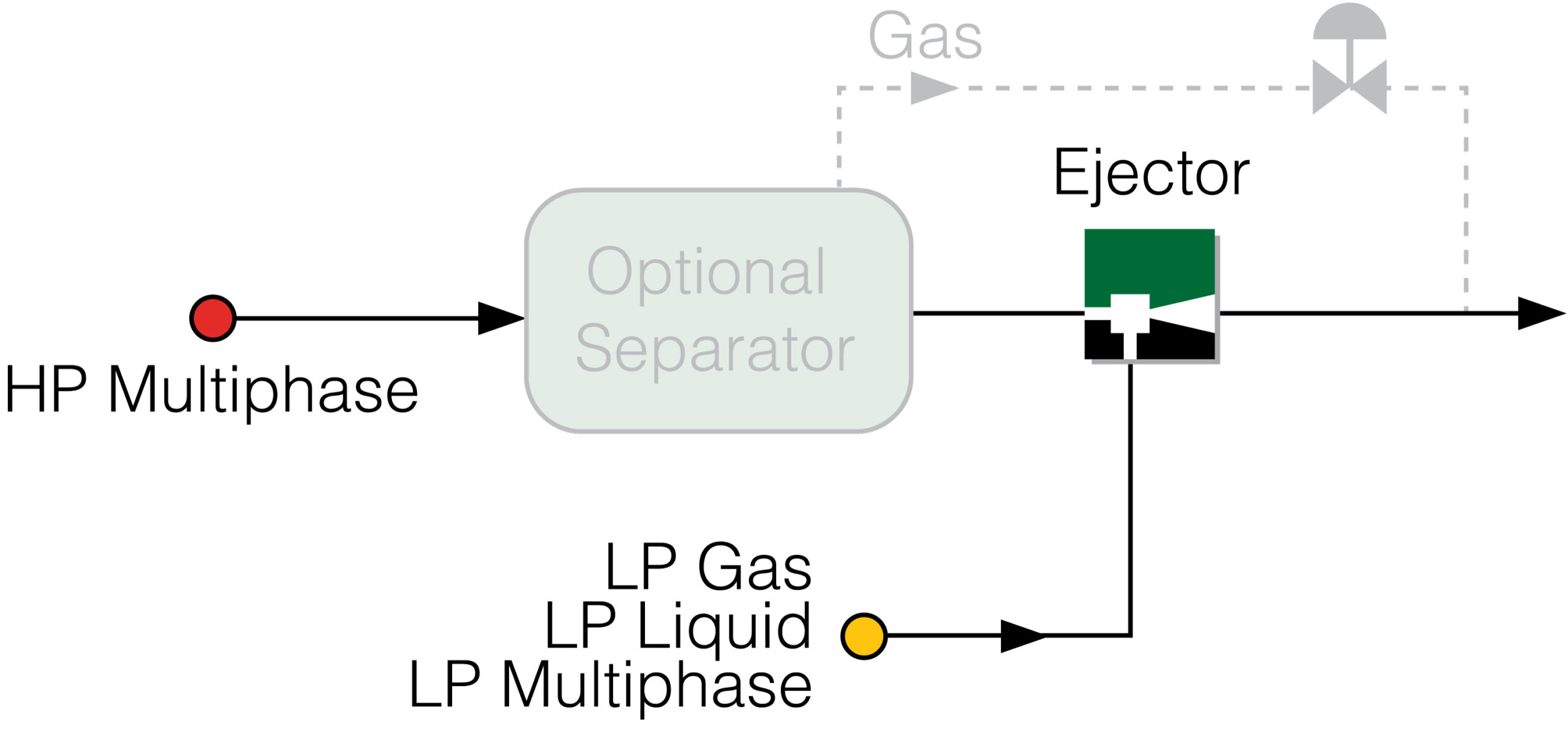

Another example is when an HP multi-phase well to being ‘choked’ to a lower export pressure, which is a waste ‘usable’ energy. Instead of wasting energy, the choke valve is bypassed and the HP multiphase flow is directed to an inline ‘flow conditioner’ to separate HP gas and HP liquid. The HP liquid is then used to ‘drive’ an Ejector, to lower the pressure on a LP single or multiphase (often marginal) wells thereby boosting production and sometimes bringing ‘dead’ wells back to life. Once the LP flow has been entrained it mixes with the HP motive liquid within the Ejector and is then compressed to the export pressure. The HP gas from the flow conditioner by-passes the Ejector and is commingled downstream of the Ejector for export.

It can also be an attractive solution to use a single phase liquid delivered by a HP pump to drive an Ejector for boosting production of a multiphase LP well.

To maximise the opportunity as far as possible, our Universal Design Ejectors provide an extended operating window. The Ejector ‘follows’ and adapts to the high-pressure well curve, as it changes over time, through use of different sets of Ejector ‘internals’. Of course, at some point, the high-pressure well pressure will decline to where the Ejector opportunity will end. However, the Universal Design allows for the Ejector to be relocated to another site, to be driven by another high-pressure well. So you can benefit time and time again!

Further information on our Patented Universal Design can be found here.