Transvac’s has over 45 year’s experience in the design and manufacture of Ejector-based Systems.

Our experience as an Ejector specialist extends beyond the limits of the Ejector itself. This is why a packaged system from Transvac incorporates not only the best Ejector technology, but also the most robust, proven approach to Ejector control, instrumentation and piping design.

Our packaged systems are all designed in accordance with all your site-specific standards and requirements. This includes Offshore Oil & Gas, Refinery, Utility (such as drinking water plants), Process Sites and clean/hygienic environments.

Ejector control techniques can vary greatly, dependant upon your process and fluid streams. Our experience allows us to incorporate robust, reliable control strategies into out packaged systems.

Our systems include all required instrumentation to ensure your Plant Operators have all the information they need to manage, control and monitor successfully.

A logical system design ensures trouble-free 'hook-up' to your existing facilities, whilst minimising pipe losses to deliver optimum process conditions to the Ejector.

Our System designs are 'Operator Friendly', considering valve and instrumentation location, easy access and all HSE and Client-specific requirements.

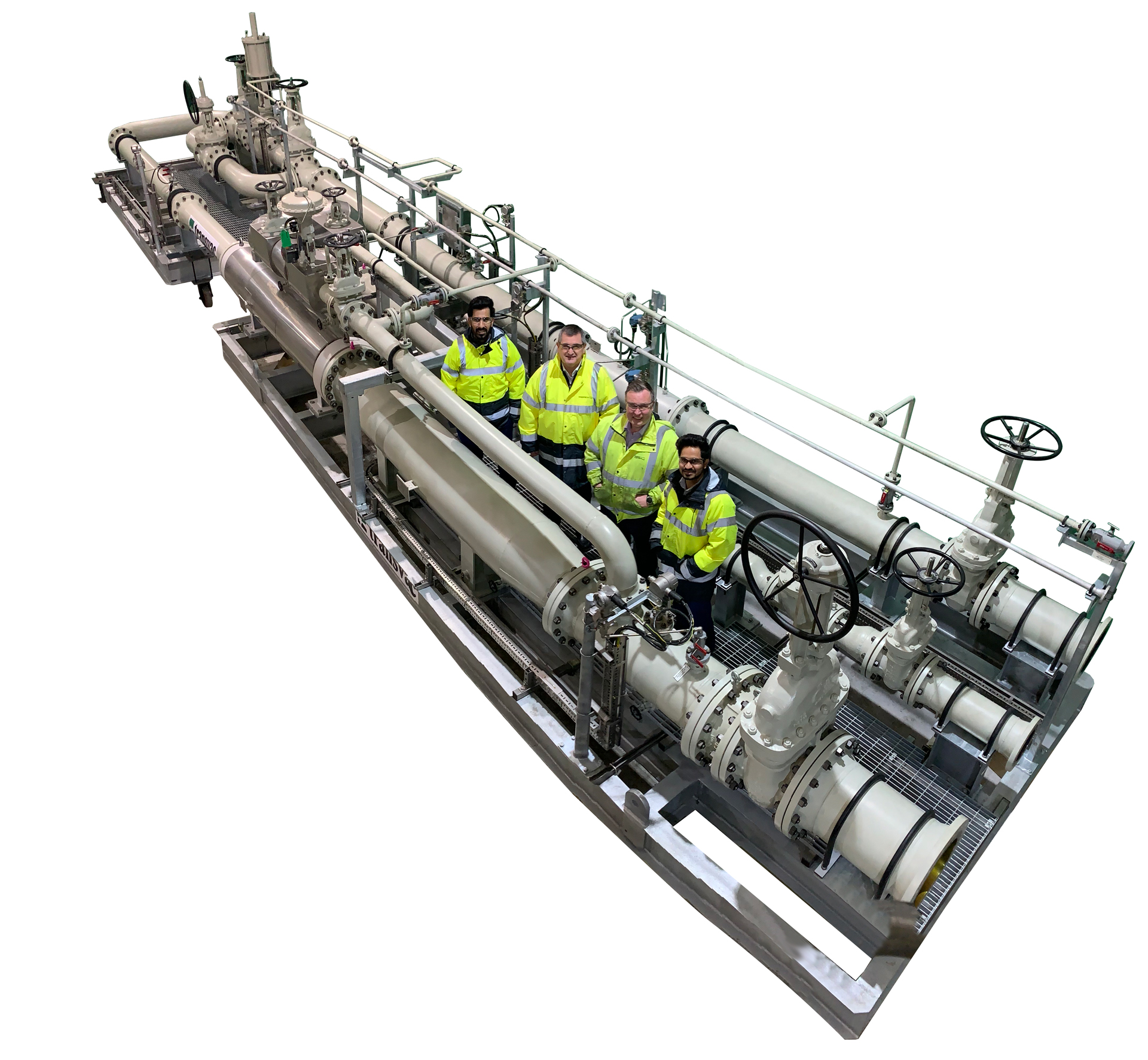

In a recent project in Saudi Arabia, a pressure let-down opportunity was identified at a gas and oil separation plant (GOSP), which operated with high- and low-pressure gas compression trains.

Transvac was able to install an Ejector package which utilised the otherwise-wasted pressure energy, lost across a valve in the high-pressure (HPPT) stream, to entirely eliminate the low-pressure (LPPT) mechanical compressor.

Not only does this Ejector package operate using existing waste energy, it eliminated the running costs and significant maintenance of the low-pressure compressor.

The Packaged System included; Gas Ejector, control valves, instrumentation, electrical, pipework/pipe spools, skid frame & supports and all required operator access.

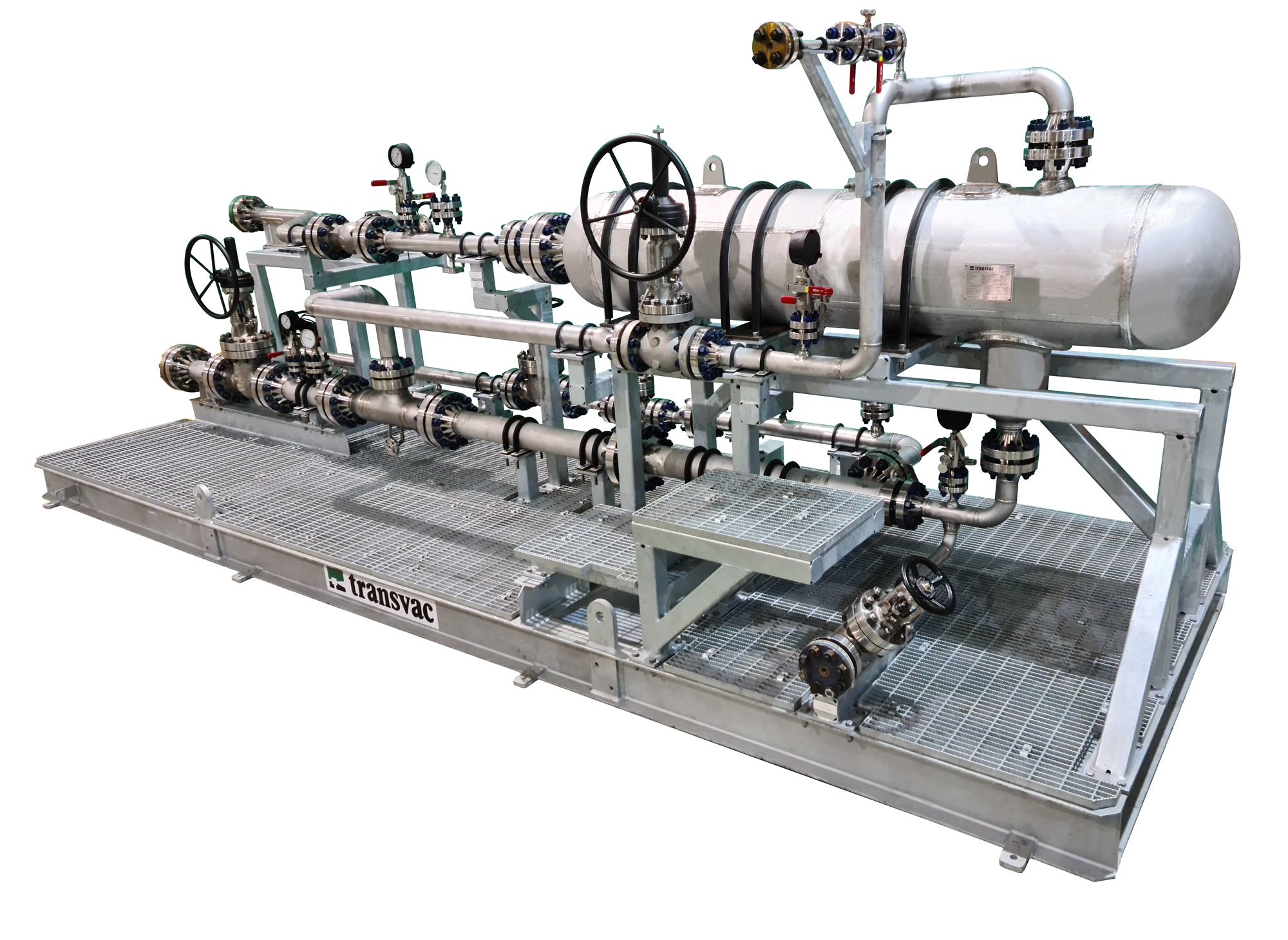

For a recent project in Saudi Arabia, a Multiphase Ejector Packaged Solution was designed and manufactured by Transvac to revive and boost production from mature, low pressure wells.

The Packaged System included; Multi-phase Ejector, Ejector Flow Conditioner, control valves, instrumentation, electrical, pipework/pipe spools, skid frame & supports and all required operator access.

TransPAC is a cost effective and highly efficient PAC dosing solution. A portable, containerised system, without the need for building or groundworks, provides a flexible, safe and secure home for your carbon dosing solution.

These packaged systems can be equipped to dose carbon from either a silo feed or a bulk-bag mount. TransPAC includes a fully programmable control panel which provides accurate and efficient dosing.

Further information on this truly turn-key solution can be found here.

Transvac offers a service to investigate operational problems and offer solutions for all types of steam ejector systems, even they may have been supplied by another manufacturer. This service can also include training for the end users engineering staff and periodic ‘health checks’ on system performance.

Please visit our Steam Ejectors page for more information.