A common question is how our Ejector designs account for the Joule-Thomson effect as the Ejector Motive stream experiences the pressure drop across the nozzle of the Ejector.

The good news is that Transvac’s Process Team will take care of this for your Ejector application – and will advise upon stream temperature at the discharge of the Ejector for your process.

This consideration most commonly arises for applications where the Ejector is handling hydrocarbons, and Engineers may be considering ‘hydrate’ formation.

Hydrates are crystalline ice like substances which can form in gas pipelines at certain operating pressures and temperatures (when water is also present) and inhibit flow. In gas production applications, passage of high-pressure gas through the nozzle of the Ejector and the reduction in its pressure downstream of the nozzle causes a drop in the temperature of the gas. The drop in temperature is, however, immediately compensated by the relatively warm, low-pressure gas (entrained via the Ejector Suction connection) mixing with the high-pressure gas. Further increase in the pressure of the mixture passing through the Ejector diffuser results in further recovery of the temperature.

The level of drop in the temperature of the gas at the outlet of the Ejector depends on a number of factors including; the flow rate and temperature of the low pressure (suction) gas, the pressure ratio and flow ratio – and the presence of liquids in high-pressure or low-pressure gas.

In most cases, there is no risk of hydrates forming within or downstream of the Ejector. Typically, the temperature drop at the outlet of the Ejector is in the range of 20% to 30% of the high-pressure or low-pressure gas, whichever has the lower value.

In very occasional Ejector projects, where the high-pressure / low-pressure gas pressure ratio and flow ratio are high, gas has the tendency to form hydrates. In such cases introducing hydrates inhibitors via the Motive or Suction line is advisable. This also applies to start-up cases where for operation reasons, it is necessary to start the Motive flow first, before starting the Suction flow.

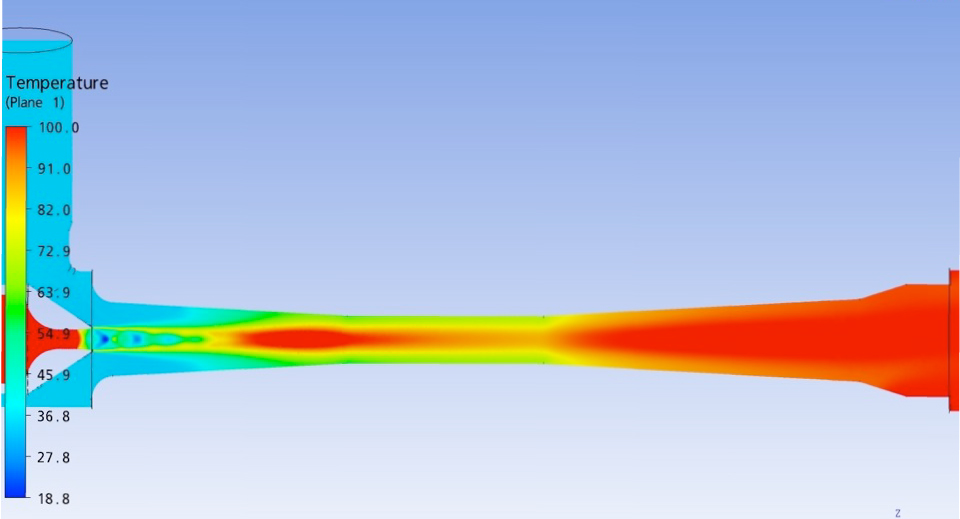

Gas expands as it experiences a drop in pressure. The Joule-Thompson effect is a physical process in which the temperature of a gas is decreased by letting gas expand. Gas experiences a drop in pressure and therefore temperature, as it passes through the Motive nozzle of an Ejector. Therefore, our process design must consider this phenomenon.

Temperature profile across an Ejector: This shows only a very localised low-temperature region after the nozzle tip, but temperature is quickly regained as the relatively warm suction gas stream is entrained and pressure is regained through the Ejector’s diffuser section.