Custom Designed Ejectors

All Transvac Ejectors are custom designed, to suit the specific requirements of each and every project. There are multiple types of Ejectors, classified by duty, connection type, material of construction etc., as detailed below. Each of these elements can be customised as required.

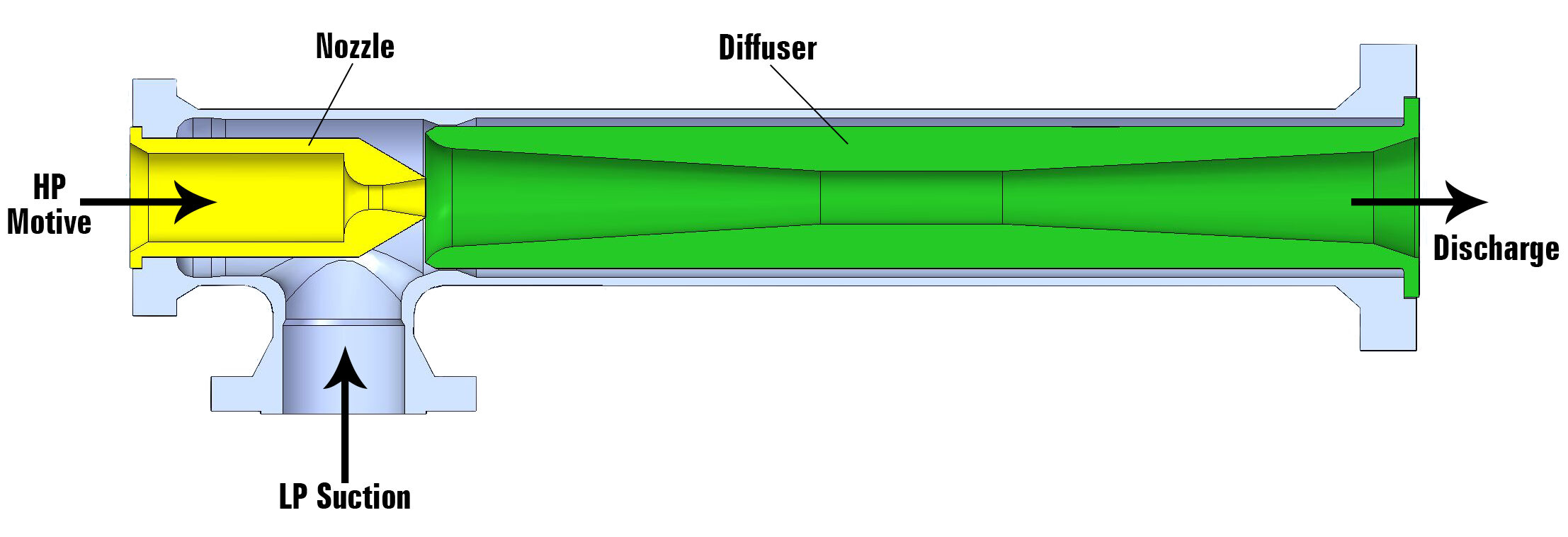

Terminology

Ejectors are also known as Eductors, Jet Pumps, Surface Jet Pumps, Velocity Spools (for Saudi Aramco) or Venturi’s.