Transvac’s High-Performance Ejectors for CCUS can help achieve Net-Zero Carbon by 2050. The unique features and benefits of Ejector technology are ideally suited to CCUS and include;

Our Ejector technology offers reduced CAPEX and OPEX for a variety of gas compression, and enhanced mass transfer applications.

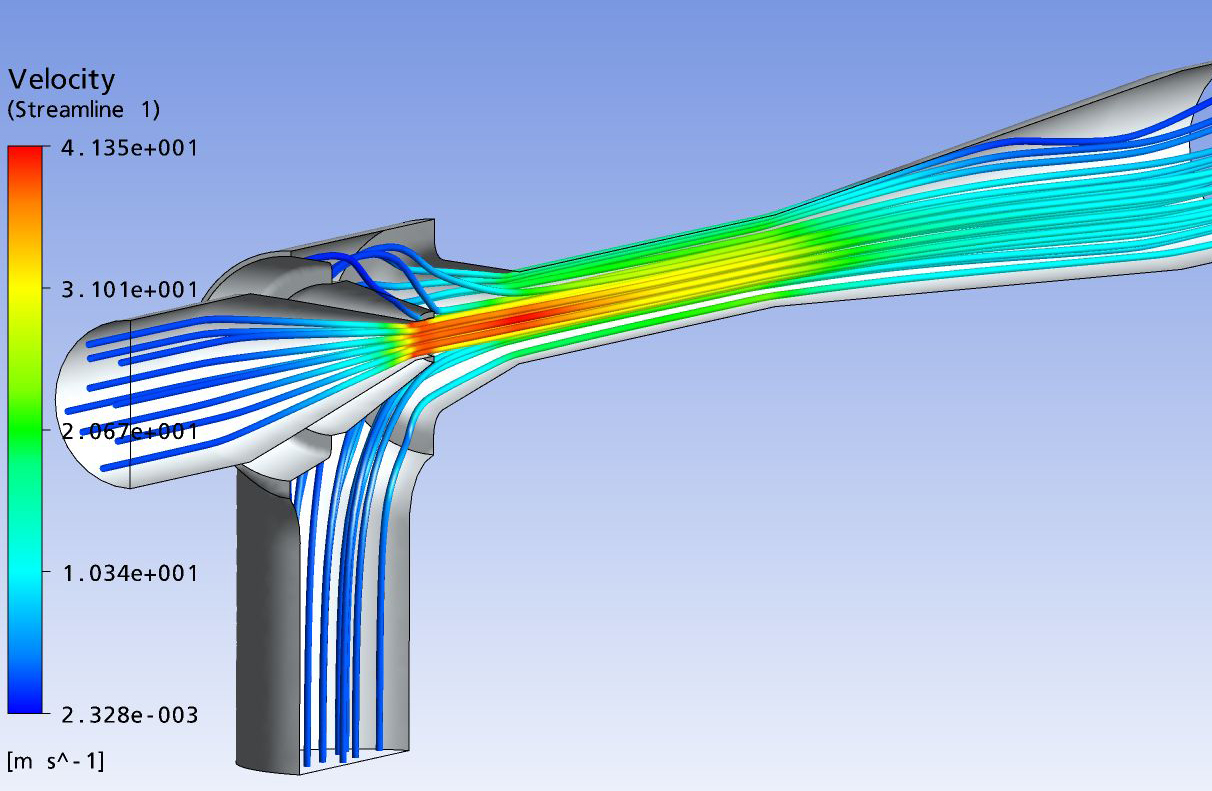

Our Ejector designs are developed through extensive CFD, and validated with ‘real world’ testing carried out at our own Ejector Test Facility.

Transvac actively collaborates with clients and academia to solve problems by integrating our Ejector technologies into new and existing applications.

One such collaboration, part funded by the Engineering and Physical Sciences Research Council, is a project with the Resilient Decarbonised Fuel Energy Systems Doctorial Training Centre at Nottingham University. It focuses on the intensification of CCUS processes, by integrating our new Ejector Technology.

We also collaborate on CCUS and related research programs with our clients, and Universities such as; Nottingham, Sheffield, and Cranfield.

Our research programs include:

We are seeking partners for collaborative projects, (either as a consortium or a single partnering arrangement) utilizing Transvac Ejector technologies in various industrial applications.

If you are considering developing processes for CO2 capture, compression or transport; H2 compression; energy storage using compressed gas; or heat pump applications, we would like to hear from you.