Transvac has gained a wealth of experience through providing custom designed Ejector technology since it was formed in 1973. Exposure to a wide range of applications across numerous sectors has equipped Transvac with detailed understanding of process design ‘best practices’ for the application of Ejector technology.

Following the establishment of Transvac’s unique Test Facility in 2010, we committed to increasing our fundamental Ejector technology process knowledge and intellectual property by introducing dedicated Research and Development programmes. Transvac owns all the IP and Patents generated by these various Product Development programmes.

The development programmes have been particularly focussed on generating efficient, liquid driven Ejector technology for gas compression that can be economically applied to environmental projects such as flare gas recovery, CCUS and other energy-saving applications. We are committed to developing unique Ejector technology that can help towards achieving Net-Zero Carbon, which is one of the biggest global challenges of our time.

Transvac’s proprietary procedures, used in the process design of our Ejector technology, have been validated by operational experience, physical testing and CFD (Computational Fluid Dynamics) studies (delivered by our in-house team of dedicated CFD specialists).

Transvac has a large number of experienced qualified Chemical and Mechanical Ejector specialists throughout its business that work closely with clients on the use of Ejector technology from the conceptual stage, through to FEED, detailed design, installation and commissioning.

We can offer design support for complete skid mounted Ejector packages including associated pipework, valves, instruments and electrical items.

Transvac can support / advise clients on HAZOPs, off-design operation, noise generation, temperatures, handling multiphase streams etc.

Where more detailed assistance is required at an early stage of a project, Transvac can also perform a paid study to assist the client’s engineering team on the application of Ejector technology.

Transvac has developed its own property software for Internal use and Online Software that clients can use when screening potential Ejector applications.

Proprietary software used by Transvac for the process design and development of Ejector technology include:

There as some simple ‘Rules of Thumb’ / guidance that can be useful when assessing how to apply Ejectors.

The table indicates what fluids work effectively when using Ejector technology.

For example, Gas as a motive fluid can effectively entrain and compress a suction Gas, but performance is very limited when entraining a suction Liquid.

Ejectors can be designed to work with many different motive fluids including Diesel, Amine, Oil, LNG, Hydrogen, Condensate, Produced Water, Multi-phase and many other fluids.

For Multi-phase Oil & Gas applications, such as boosting production from Multi-phase wells, we have a range of options to offer efficient and robust operation. Visit our Production Boosting page to learn about these options.

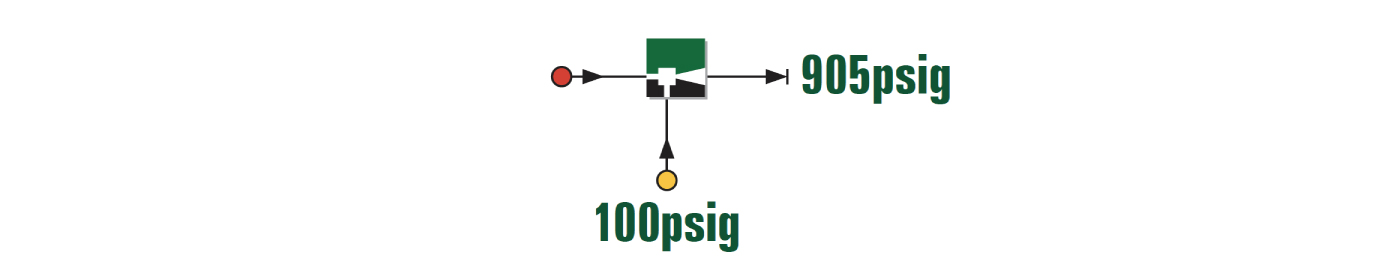

High-pressure Gas compressing low-pressure Gas to an intermediate pressure.

Compression Ratio (K): Typical limitation for a single stage Gas Ejector is approximately 8.0.

E.g: For a Suction (LP) Pressure of 100psig (115psia), the typical limiting Discharge Pressure is 8 x 115 = 905psig (920psia).

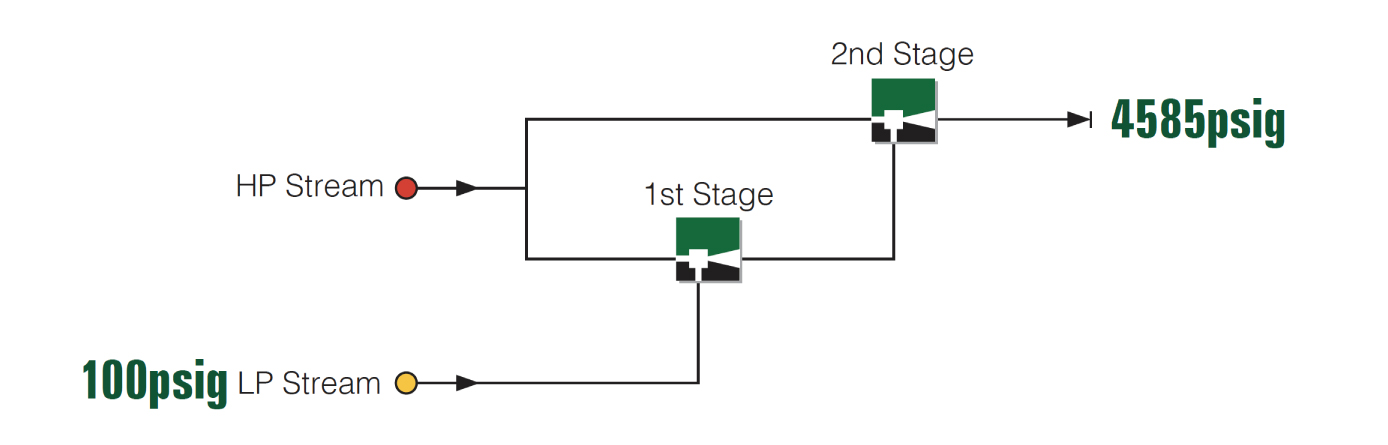

Higher compressions can be achieved by staging Ejectors together.

E.g: With a 1st Stage compression of K=8, and a 2nd Stage compression of K=5, the total compression of the two stage Ejector set is 8 x 5 = 40.

Higher compressions can be achieved by staging Ejectors together.

E.g: With a 1st Stage compression of K=8, and a 2nd Stage compression of K=5, the total compression of the two stage Ejector set is 8 x 5 = 40.

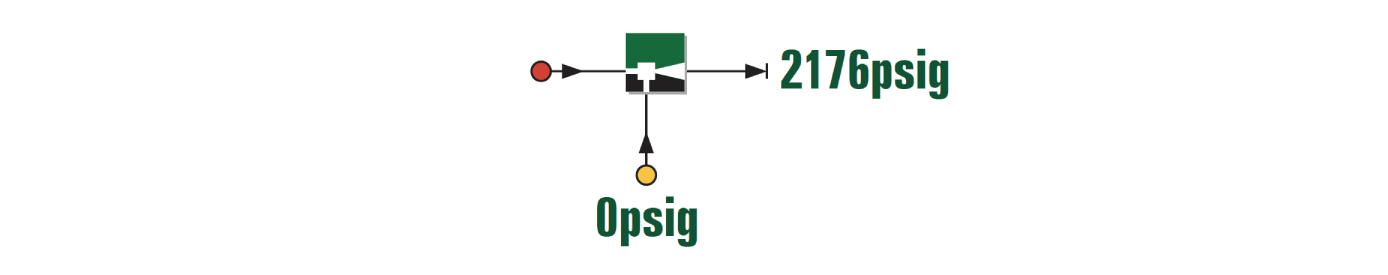

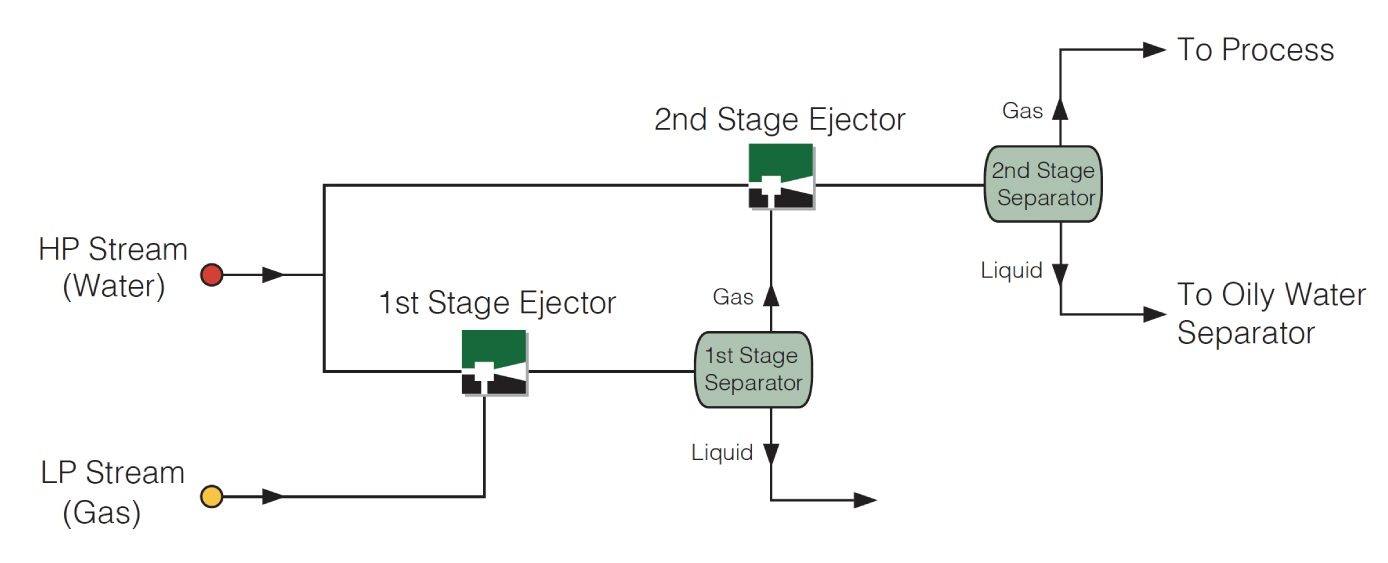

High-pressure Liquid compressing low-pressure Gas to an intermediate pressure.

Liquid-Gas Ejectors are capable of very high compressions in a single stage. Compressions in excess of 0 to 2176 psig are possible, which enables Liquid-Gas Ejectors to be used for direct gas injection into wells or caverns.

Although high compressions can be achieved in a single stage, with LJC’s, it is often beneficial to use two stages. For applications where the requirement is to compress gas greater than 300 psig, it is sometimes more efficient (less motive water required) to stage Ejectors in series.

All Transvac Ejectors operate according to their ‘design point’, provided the process conditions (at the motive, suction and discharge connections of the Ejector) are as expected.

However, many industrial processes cannot provide completely ‘fixed’ process conditions at the motive, suction and discharge connections of the Ejector. There will be some ‘natural’ variations in flow, pressure, temperature or composition of the process streams. These variations will have some effect upon the performance of an Ejector as they move further away from the design point.

To address this, Transvac takes a safe, conservative approach to our process design by ensuring the Ejector will still operate as required – even in the ‘worst operating case’. To do this, we work with our Clients to establish, for each process stream, what (if any) variations can be expected. In simple terms, to determine this ‘worst operating case’ for the Ejector, we ask;

These two questions can be answered by understanding;

When determining ‘worst case’ process data for your Ejector application, it is important to be realistic in your assessment. It can be tempting to add extra ‘safety margin’ above and beyond the realistic worst case for each respective data point. This approach may result in an Ejector design that demands far more Motive energy than is actually required – worse still, it could make the whole Ejector application not viable, due to a lack of available Motive stream. Even if a Motive stream is available, in normal realistic operating conditions, the Ejector would be operating in a less efficient manner, needlessly wasting valuable energy.

We assess temperature profiles for each Ejector project, including Joule-Thomson effect. We also advise best practice to mitigate hydrate formation downstream of the Ejector.

Transvac’s Process Team carry out detailed stream analysis, which is used to ensure suitable materials of construction are selected.

Transvac can carry out detailed FEED, feasibility or design study work as required. Tapping into our extensive Ejector experience is a great way to get your Ejector project off to a solid start – avoiding costly complications further down the line.