Transvac can supply Ejector designs that reliably handle abrasive fluids which would normally cause erosion to standard metallic materials.

Considerable experience has been gained over many years providing Ejectors for pumping sand slurry, flare gas recovery (using liquids), mineral mining and subsea processing applications.

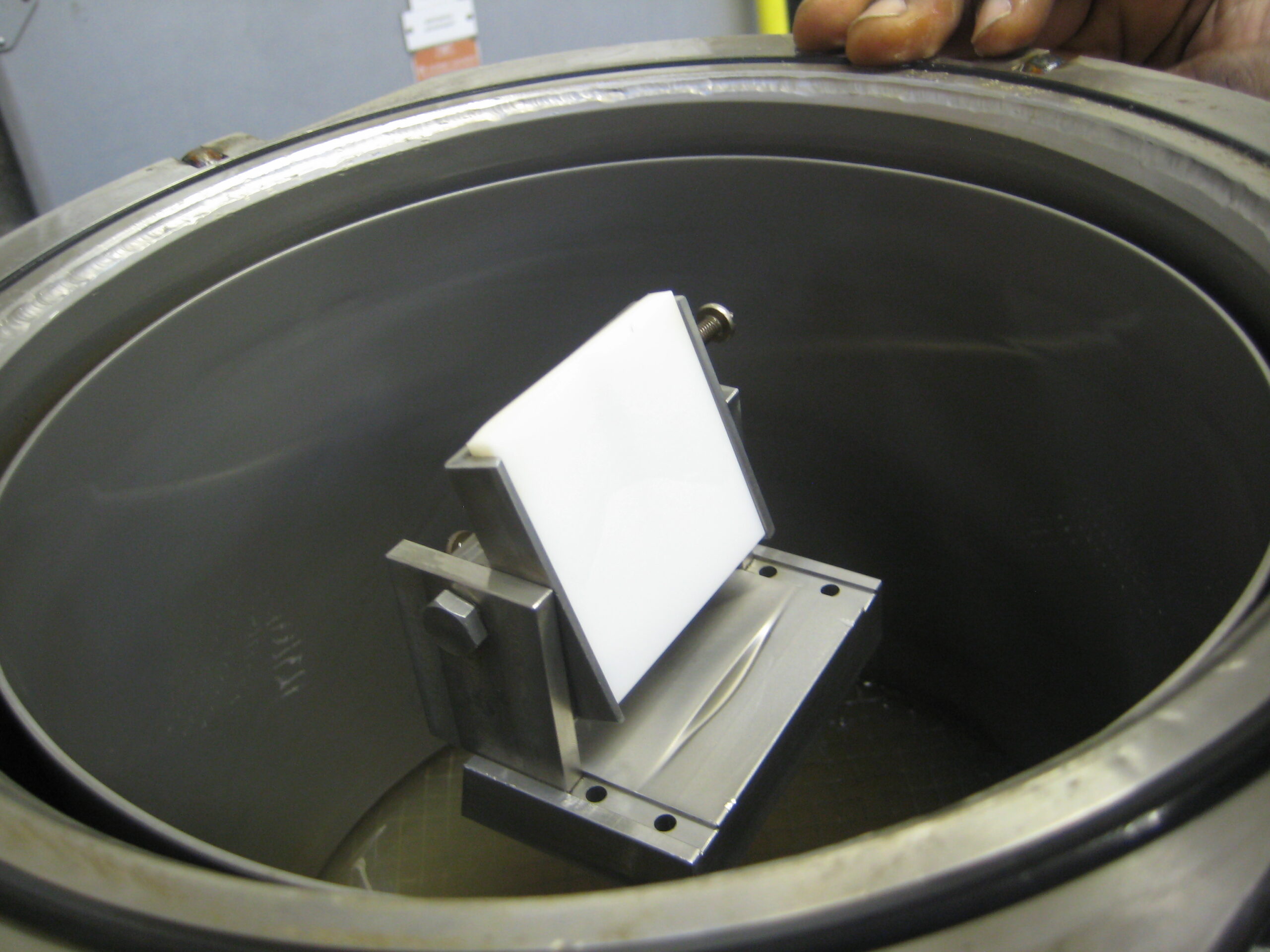

Transvac has also performed in-house CFD studies and commissioned a long-term erosion testing programmes at a specialist Team at Southampton University to determine the most appropriate grades of abrasion resistant materials for different Ejector applications.

Erosion testing has been performed on various grades of ceramics and tungsten carbide, along with comparative testing of various metallic materials.