Flare Gas Recovery Ejector Project Wins High-Profile Award at Adipec

A number of Flare Gas Recovery Ejectors have been successfully deployed to date, receiving great feedback from Operators (many of which are already looking to roll-out the same solution at multiple further sites) and receiving a number of high profile industry awards.

Most recently, Saudi Aramco won ‘Breakthrough Technological Project of 2019’ at the Adipec Awards in Abu Dhabi, November 2019. For Aramco, this project was their first high-efficiency Ejector based Flare Gas Recovery project.

Client Comment

Upon winning the award, Aramco published a news item which captures their positive project experience as well as vision for future deployments;

“South Ghawar Producing Department (SGPD) garnered the award for its innovative Flare Gas Recovery System (FGRS), which has the potential to be a game-changer in the oil and gas industry.SGPD’s project was selected out of more than 600 submissions from all over the world. The award was just the latest in a series of honors bestowed upon SGPD for its unique design that is tailored to gas-oil separation plants (GOSPs).

The solution has resulted in significant cost-avoidance, and the recovery of nearly all flared gas, reflecting positively on Saudi Aramco’s environmental stewardship. Conventional systems use a compressor to recover the flared gas, and the compressor needs auxiliaries such as drums and coolers. Such a complex system is not economical, with a payback period approaching 10 years.

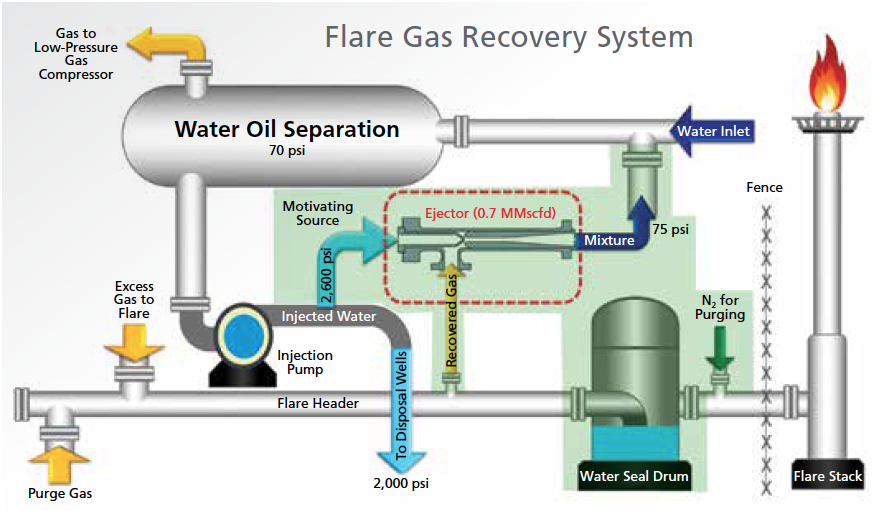

Saudi Aramco’s innovative design capitalizes on the specifics of the company’s GOSP design, and matches these with the characteristics of an Ejector to recover the flared gas. High pressure injection water, which is available from the discharge of the water injection pumps, is used to boost the pressure of the gas recovered from the flare header by using a two-phase ejector. The mixture of the gas and water is sent to an existing water oil separator, where the gas is recovered in the gas compression system.

This approach, which has not previously been used in GOSPs worldwide, limits the need for new equipment – to just an ejector and a flare seal drum – with simple controls. The ejector-based system is promising in terms of low cost, simple operation, and convenient control. Furthermore, the elements in the design are typical for oil processing facilities worldwide, making the scope of the application global”

Further Project Awards – Green World Global Awards

The same project was also recognized at the Green World Global Awards in Vietnam, October 2019, with a first place ‘Gold’ showing for its innovative approach to Flare Gas Recovery. The Green World Awards are chosen among the top tier of the Green Apple Awards, reflecting efforts by companies and organizations’ remarkable work in the field of environmental protection. Saudi Aramco SGPD Manager commented;

“This achievement is a natural outcome of Saudi Aramco’s leadership role in environmental protection and its unlimited support to all environmental initiatives and solutions. This approach is expected to reduce the return on investment period from 10 to only three to four years, making a considerable impact on the company’s environmental stewardship initiatives”.

If you would like to find out more about this award and the technology behind it, please contact us.