We are very proud of our skilled Manufacturing Team and their quality of workmanship. Transvac has over 50 years’ experience in the design and manufacture of Ejector technology. We offer a unique one-stop-shop service, capable of supporting the most challenging of Ejector projects – with all key processes controlled in-house at our facility, in Derbyshire, UK. This is important because it guarantees we can deliver our projects on-time and to specification.

Although Ejectors appear to be simple pipework, they do in fact require a very specific and specialist approach when it comes to manufacturing. A general fabrication facility, which may typically produce vessels and pipework are rarely capable of producing reliable, efficient Ejectors. In contrast to this, Transvac’s Manufacturing Team has a world-leading understanding of Ejector manufacture and the specific workflows required between welding and machining required to ensure design tolerance, concentricity and a high quality finish is met, every time.

Our Team is also very experienced in manufacturing Ejectors from many materials including many exotic alloys and wear resistant parts for specialist applications.

We have invested over £2.5million in our manufacturing facilities alone to give us full control of all production output and product quality. As well as machining, welding and lifting/crane facilities we are also equipped with a hydro-test bay for product pressure testing and a temperature controlled onsite spray paint booth, with NACE level 2 paint inspection.

We have a range of large capacity CNC Lathes, Spark Erosion Tools and Vertical Machining Centres (VMCs), with a recent £100k investment into a new VMC system.

Internal taper machining is one of our key strengths and we have developed our own set of proprietary boring tools, allowing for the precise milling of extremely long bores.

With our large capacity CNC capabilities, we can manufacture Ejectors up to 24” NB (which covers over 95% of all Ejector sizes we offer). Our experience in Spark Erosion Tooling and VMC’s allows us to three-dimensionally machine extremely accurate very complex Ejector components.

Welding is one our core competences and we pride ourselves on fully meeting the project specifications of our client. Transvac has worked with most of the major oil & gas operators including Aramco, Shell, ExxonMobil, ConocoPhillips, OXY and many others.

We understand that Ejectors often operate at very high pressures and in hazardous environments and that precise, integral welds are essential and mandatory.

We are certified to ISO 3834-2 for the “Quality requirements for fusion welding of metallic materials”. See our Certifications here.

During manufacturing we fully segregate ferrous and non-ferrous metals and have a dedicated clean welding environment for the assembly of non-ferrous metals. Our welding consumables are stored in a dedicated climate-controlled environment to prevent degradation.

Our welding capabilities include TIG, MMA, MIG/MAG, FCAW & SAW with welding procedures and personnel qualified on a large range of materials such as Carbon steel, LTCS, Cr-Mo, Austenitic Stainless Steel, Duplex/Super Duplex, 6Mo, Alloy 625, Alloy 825, Hastelloy C276 and others.

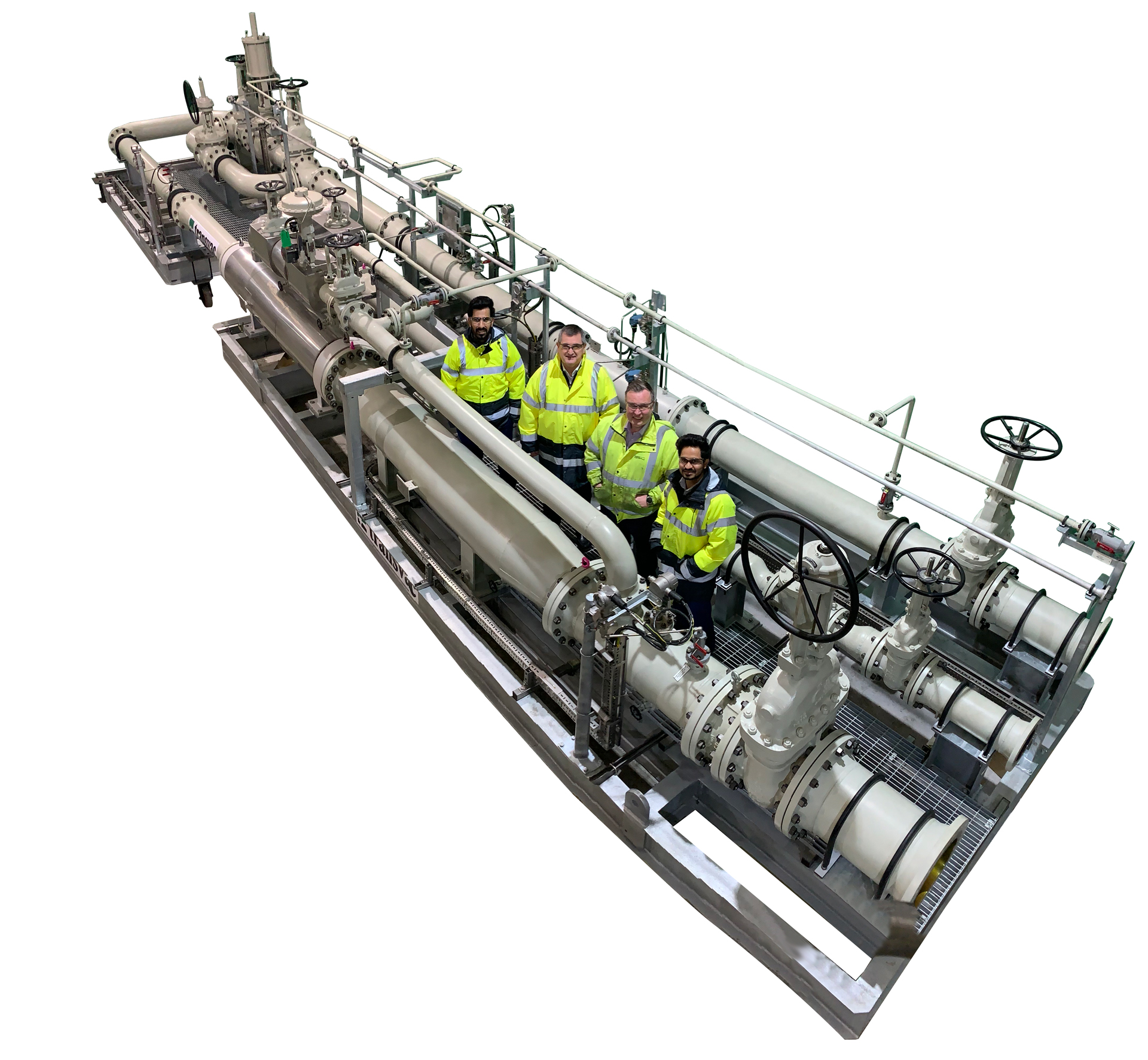

We have a dedicated assembly area that gives us the flexibility to assemble large Ejectors and skid packaged Ejector systems.

Transvac is experienced in handling many types of materials and the handling requirements needed.

We maintain limited material stocks which are all registered, segregated and stored in accordance with our quality system by a dedicated Materials Handling & Controlling team.

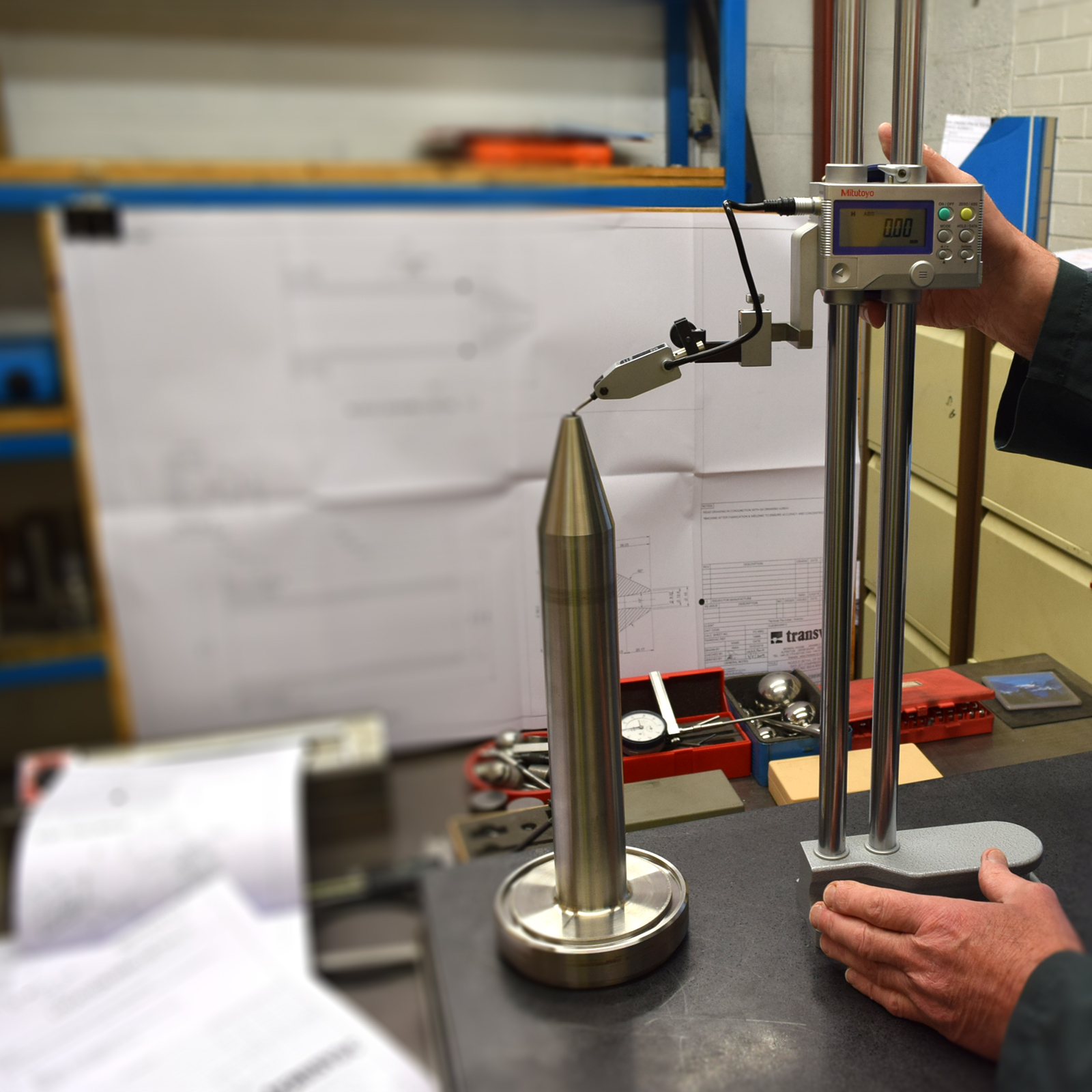

We have a rigorous, gated inspection regime throughout our manufacturing process co-ordinated by our dedicated Inspection Department. All component parts are checked and verified prior to being released for assembly. These in-process checks are a vital part of our quality assurance process, helping us guarantee our products conform to the required tolerances, surface finish, concentricity, design code and client specifications.

In addition to dimensional inspections we also have the in-house capability to perform welding inspection including

MPI, DPI, PMI and Hardness Testing, with technicians certified to CSWIP, PCN II and ASNT II.

Our equipment used to ensure compliance is meticulously maintained, catalogued and calibrated to national standards.