Transvac Steam Ejectors; also known as Steam Jet Ejectors or Steam Eductors are used for creating vacuum across many industries. Applications range from coarse vacuum single stage Steam Ejectors; such as rapid evacuation Ejectors (also known as ‘Hoggers’) up to 5 stage Steam Jet Ejector Systems fully packaged to produce vacuum levels of up to 25 microns Hg abs.

Modern, energy efficient Steam Jet Ejector Systems offer many advantages when compared with other vacuum producing systems, such as mechanical Liquid Ring Vacuum Pumps, Rotary Vane or Screw type Vacuum Pump. Steam Jet Ejectors can often utilise surplus motive steam sources on site and need no additional energy.

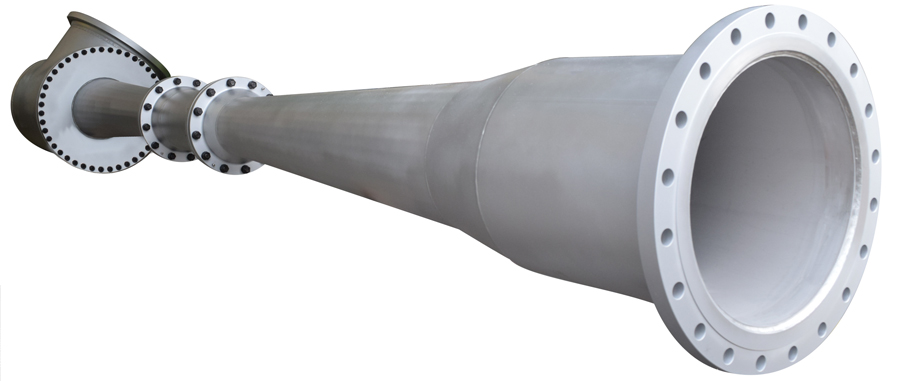

Standard Steam Ejectors for non-corrosive applications, such as Power Generation.

Stainless Steel and Carbon Steel are most commonly used

for Standard Steam Ejector applications.

For corrosive applications, such as Fine Chemicals and Pharmaceuticals.

Corrosion resistant Steam Ejectors can be offered in exotic materials

including Hastelloy, Titanium, Graphite and PTFE.

Transvac design and manufacture a huge variety of custom-designed Steam Ejector Systems in both Standard and Corrosion Resistant materials. From single-stage Steam Ejectors to fully packaged multi-stage systems, incorporating Direct and Indirect Contact Condensers.

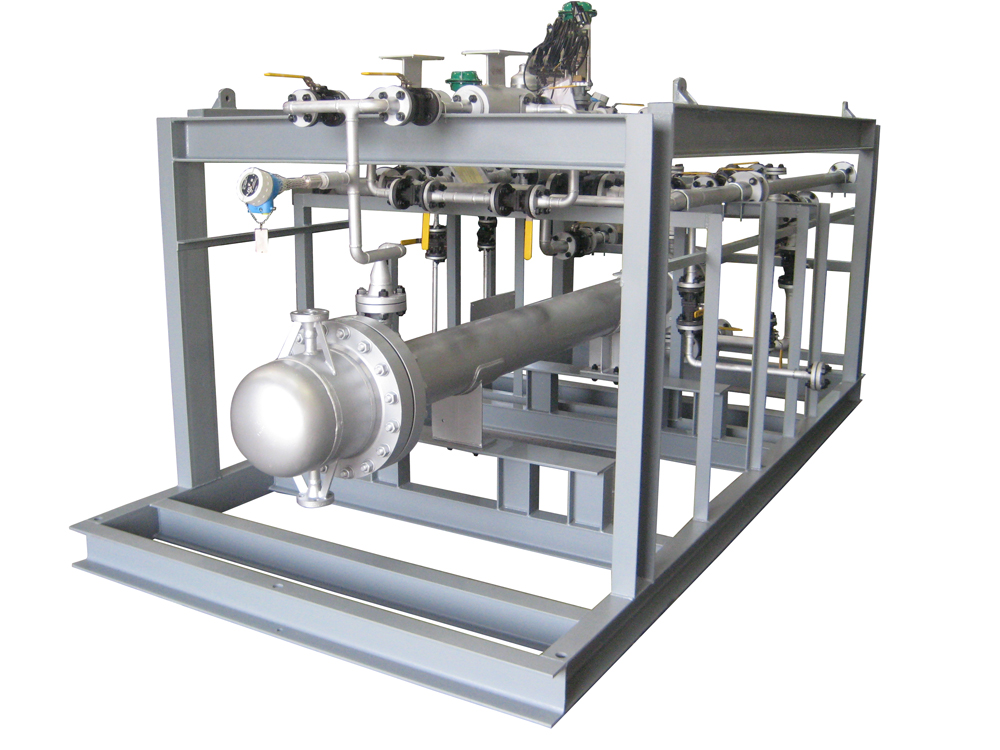

Transvac Ejectors can be combined with mechanical Liquid Ring Vacuum Pumps into a compact vacuum system. Combination systems are available with one, two or three stages of Steam Ejectors combined with single or two stage Liquid Ring Vacuum Pumps and Condensers (Direct or Indirect Contact).

For these systems the Liquid Ring Pump is very effective at rapidly producing a coarse vacuum with the Steam Ejectors creating higher vacuum levels. These low-level, skid mounted systems are versatile in handling both wet and dry loads.

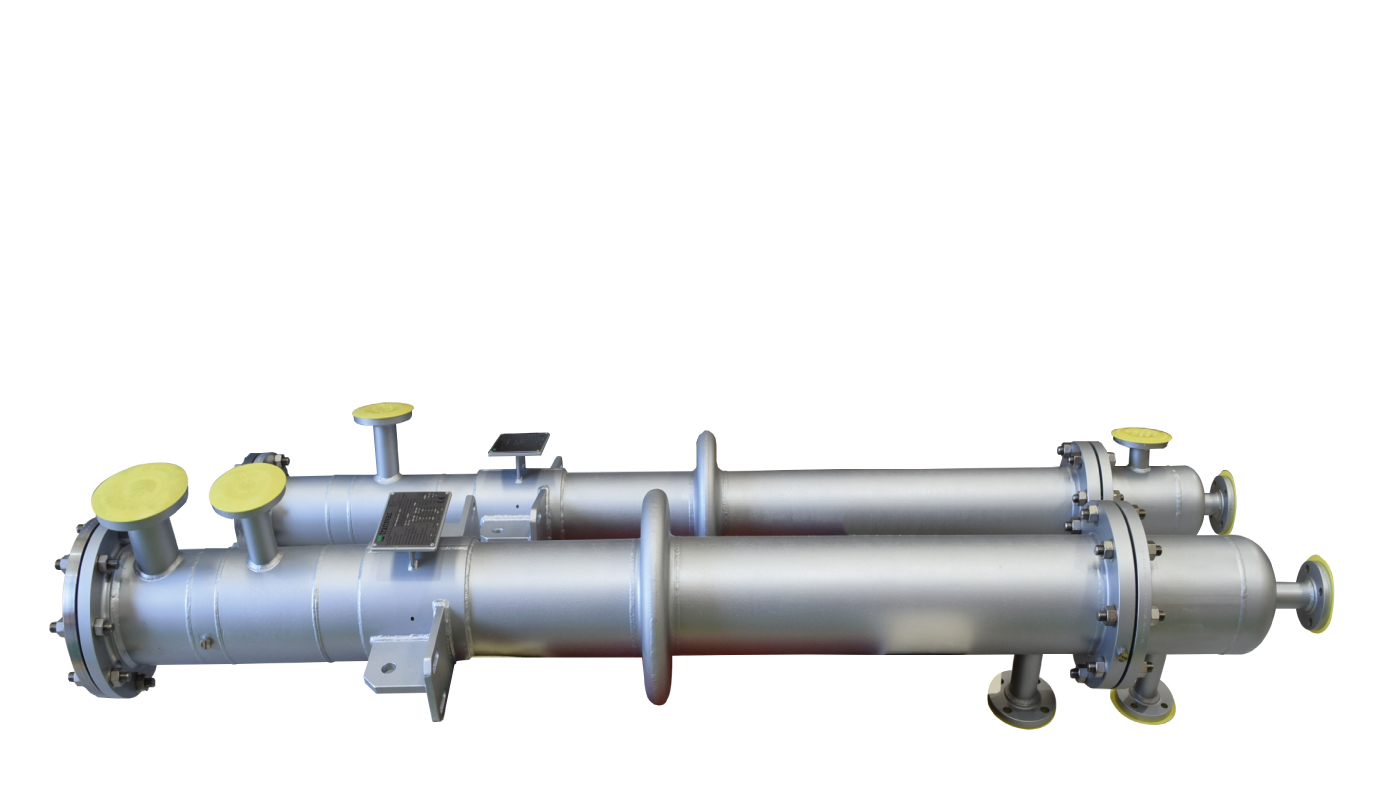

Transvac offers a full range of Direct and Indirect Contact Condensers for either barometric or low-level operation. Indirect or Surface Contact Condensers (Shell & Tube, Plate or Graphite Block) are used when the condensed fluid and cooling medium (usually water) must be kept separate.

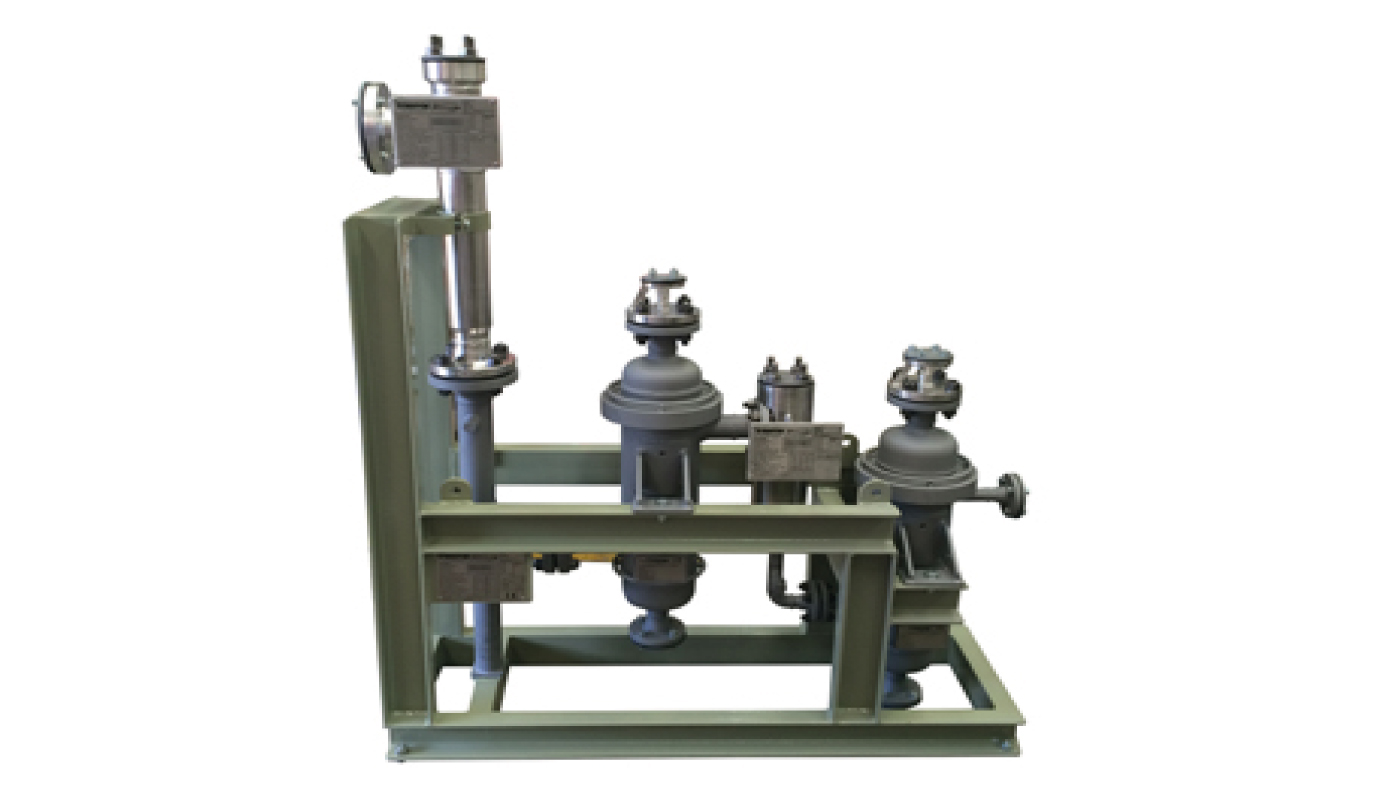

Direct Contact Condensers (Ring & Disc or Spray type) are used when mixing of the condensed fluid and cooling medium is acceptable.

Shell and Tube Inter and After-Condensers supplied as part of a Steam Ejector package

Small Steam Ejector System with Direct Contact Inter and After-Condensers

Due to the significant reduction in the number of Steam Ejector suppliers servicing the UK & Eire process industries in recent years,there are many end users experiencing difficulties in maintaining existing steam jet vacuum systems in operation. Using expertise and experience gained over 40 years as a designer and manufacturer of Steam Ejector systems Transvac is in a unique position to address this problem.

Transvac offers a service to investigate operational problems and offer solutions for all types of steam ejector systems, even they may have been supplied by another manufacturer. This service can also include training for the end users engineering staff and periodic ‘health checks’ on system performance.

As a designer and manufacturer Transvac can replace individual components or complete systems in standard or corrosion resistant materials. The service covers Steam Ejector vacuum systems, Steam Ejector / Liquid Ring Pump combination vacuum systems, Thermocompressors and Air Ejectors.

Transvac provides a support and maintenance service to UK-based legacy Ejector packages, vacuum systems and ancillary equipment. For decades these systems were installed to the process industries for a range of vacuum duties. Unfortunately, these sytems are often unsupported and therefore operate inefficiently and outside of their intended design envelope. Transvac’s troubleshooting team provides a full system inspection and can offer replacement parts where required. In many cases, significant cost savings can be made as these inefficiencies are resolved.

Please note: We can only offer service support for UK based systems only.

For further information on our support & maintenance service, please contact us here.