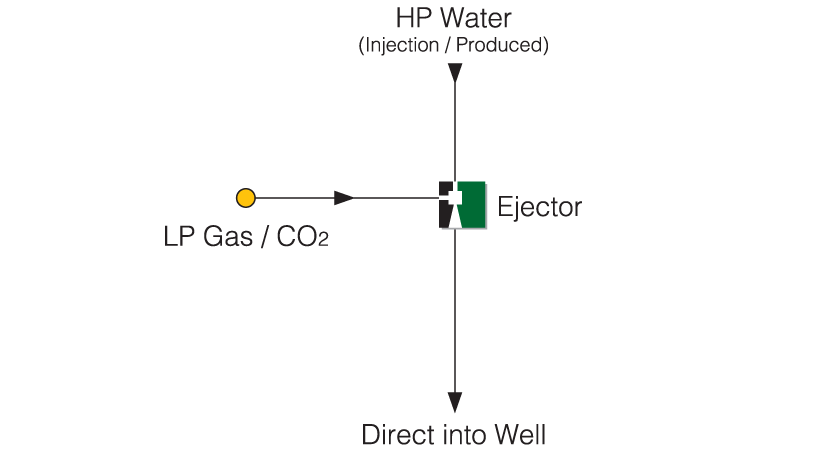

Transvac Ejectors now have the capability of achieving very high discharge pressures and can compress gas from 0 to 2150 psig in a single stage. This means Ejectors can now entrain low-pressure gas (such as CO2 or flare gas) and discharge the multi-phase flow into an underground formation, similar to the SWAG process (simultaneous water and gas injection).

Existing injection water pumps can often be used to supply high pressure water to the Ejector which entrains and compresses the CO2 or waste gas. The Ejector then discharges the compressed gas/HP fluid back down-hole. In many instances, the reinjected fluid is used for resevoir flooding/EOR techniques – an additional benefit.

Carbon Capture & Storage (CCUS) / CO2 sequestration can also be achieved with Transvac’s Liquid Jet Ejectors. The technique is the same, using HP water to gather, compress and reinject CO2 into the resevoir. If water cannot be reinjected, a separation stage can be added downstream of the Ejector.

Transvac has already successfully supplied this type of system to a major Operator in the Permian Basin, USA where the gas was very sour (40% H2S).

“The Ejector is running like a champ and over-performing against the original design requirements! So far the Ejector has been taking our entire gas stream at about 90 PSIG suction, and raising it to about 875 PSIG on the discharge side. It just started up a few days ago, and so far we are having good success with getting it to send the total combined stream back downhole.”