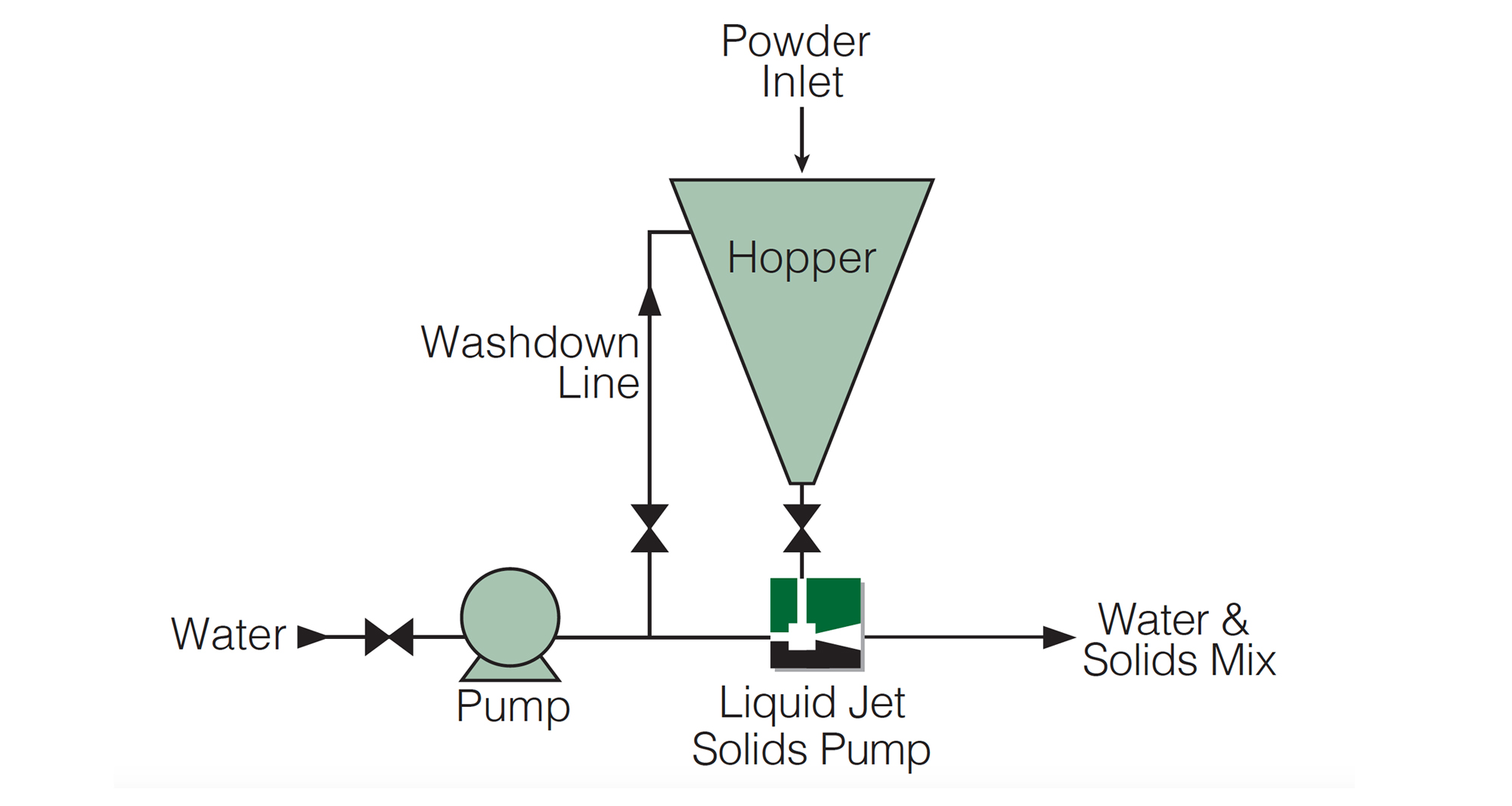

Our Liquid Jet Solids Pumps (Ejectors) offer a versatile option for entraining, dosing, mixing and pumping solids into liquids. The venturi principle offers many advantages over other types of high-shear mixing equipment on the market. Robust and highly reliable with no moving parts to wear, our units are virtually maintenance free. As such our Ejectors offer a more reliable alternative to traditional Dosing Pumps.

Available in either stationary, portable or mobile models, the custom designed Liquid Jet Solids Pump (LSP) units can be supplied as individual items or complete skid mounted systems including motive pump, valves etc.

Powder can be loaded manually or automatically using screw feeders at ground level, thereby keeping powder handling at a minimum. In many cases fluid energy from existing pumps can be used which eliminates the need for additional power. Depending upon the process conditions operation can be on a once-through or recirculation basis.

Materials of construction can be varied to suit the process environment. Stainless steel, carbon steel, polypropylene, PTFE and other materials are available with connections to suit. Where required, our products can be designed to comply with stringent hygiene requirements using polished stainless steel and sanitary fittings.

Further information on materials of construction for our products can be found here.