Air Jet Ejectors

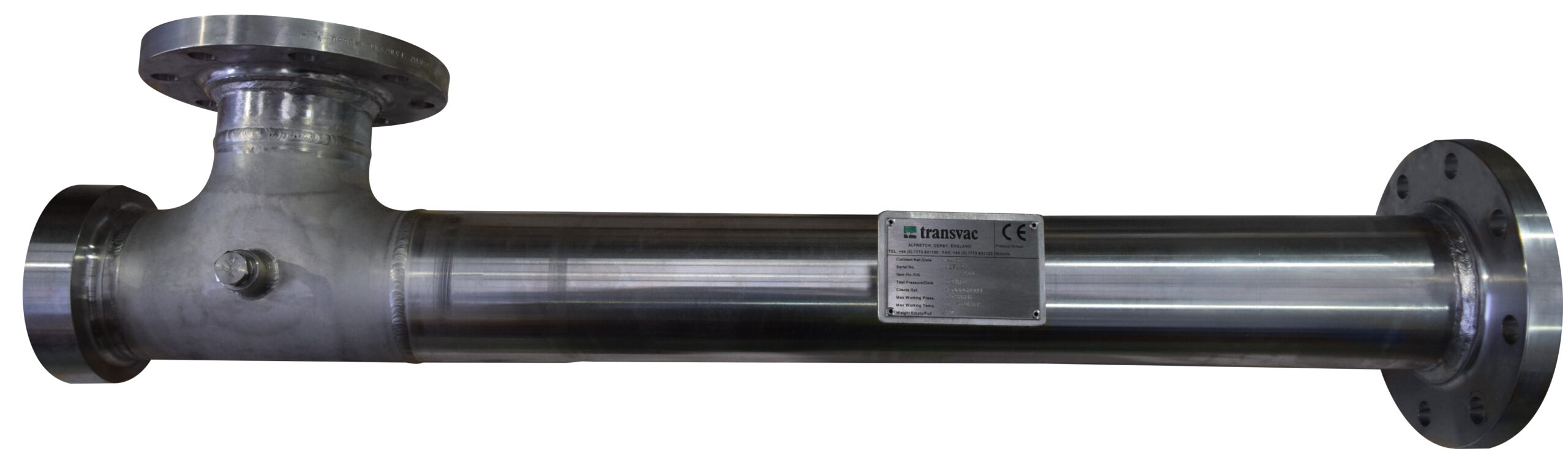

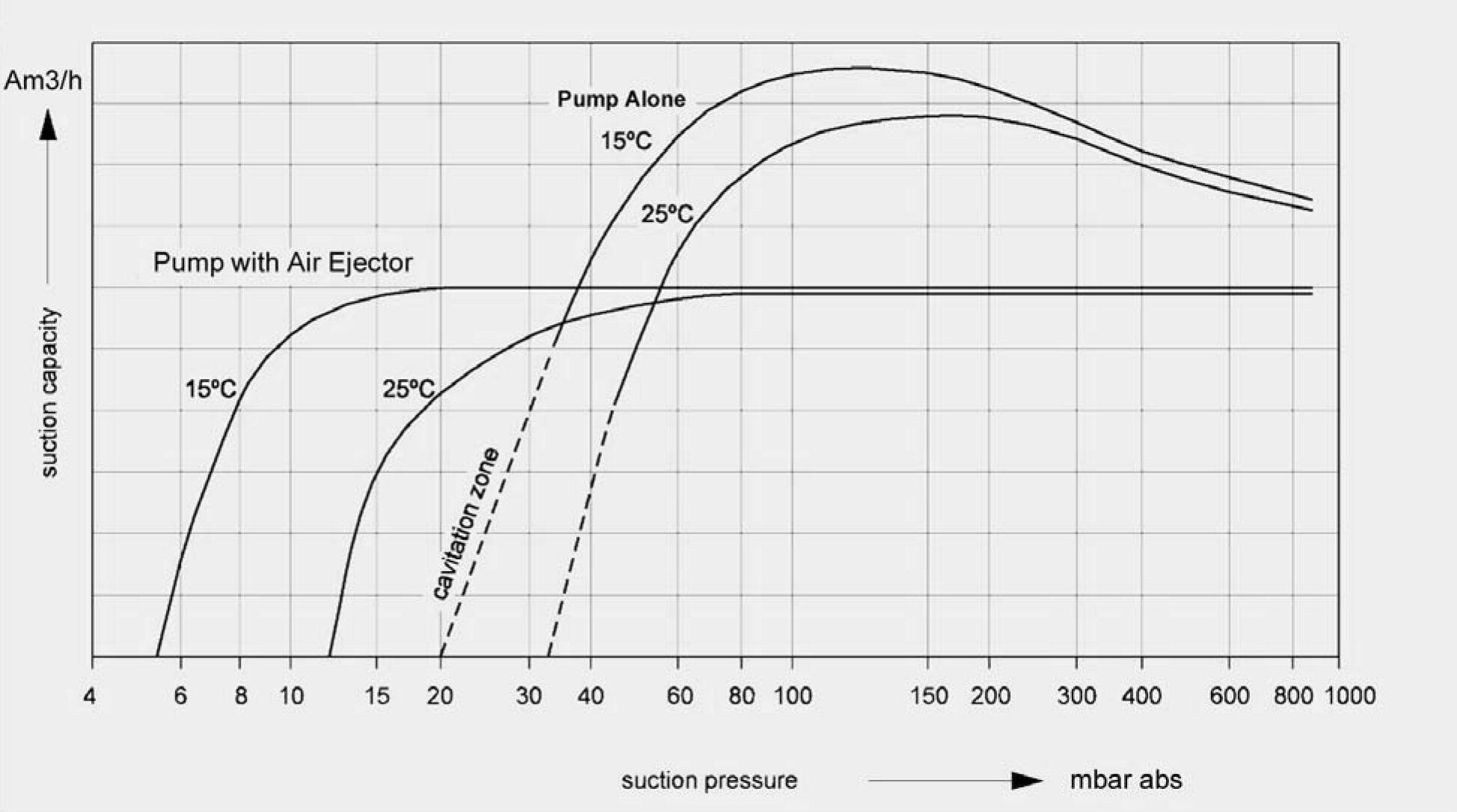

Transvac manufactures a comprehensive range of Air Ejectors also known as Air Jet Ejectors, Athmospheric Air Ejectors and Air Eductors. Air Ejectors are used to extend the operating range of Liquid Ring Vacuum Pumps, boosting performance. The inlet pressure of a Liquid Ring Pump is limited to approximately 30 mbar abs because of the vapour pressure of its seal liquid (usually water). The addition of an Atmospheric Air Jet Ejector enables the Liquid Ring Vacuum Pump to operate outside its cavitation range allowing operation down to nearly 4 mbar abs.